Pressure Vessel Mechanical Cleaning 2025

Pressure Vessel Mechanical Cleaning

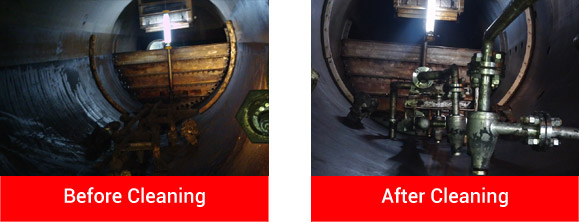

Confined Space Entry & Pressure Vessel Cleaning

At Petrotec Services and Rentals, we have developed comprehensive procedures and risk assessments for the safe and effective cleaning of pressure vessels, including inlet separators, test separators, hazardous and non-hazardous drain tanks, and more. Our team is highly experienced in confined space entry and offshore pressure vessel cleaning, ensuring the highest safety standards and operational efficiency.

We use a fleet of Ex-proof specialized equipment that is designed to meet offshore space limitations, providing the necessary power and functionality for safe, precise cleaning operations. Our workforce is extensively trained in confined space entry protocols, with a focus on maintaining strict safety procedures at every step.

Key Features

-

Highly Trained Operatives & Proven Procedures

Our skilled professionals follow industry-leading safety and operational procedures to ensure successful outcomes in confined space environments.

-

Specialist Equipment

We utilize Ex-proof, specialized equipment to meet the unique challenges of offshore environments and confined spaces.

-

Safety First

Ensuring the safety of our team and the integrity of the worksite is our top priority, with continuous training and a culture of safety at every level.

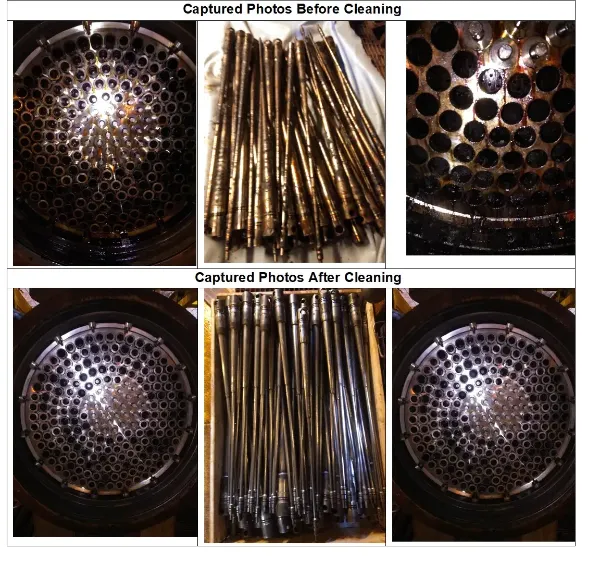

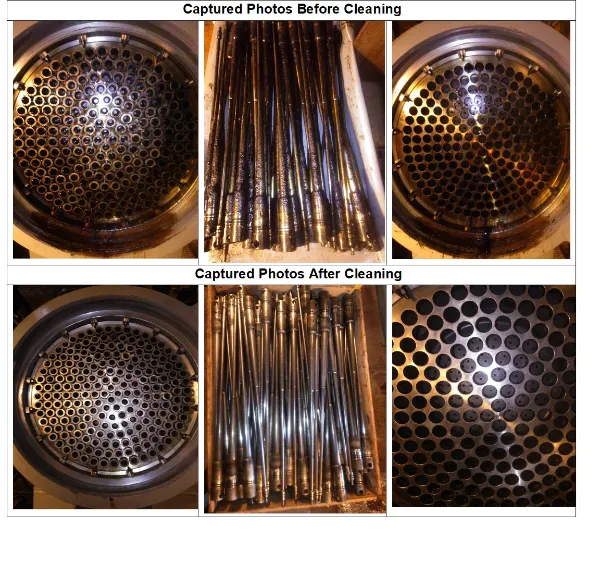

Hydro Cyclone Liner Mechanical and Chemical Cleaning

Hydro cyclone liners play a critical role in separation processes, ensuring efficient operations in various industries, including oil & gas and water treatment. Over time, these liners accumulate contaminants, reducing performance and efficiency. Our specialized Hydro Cyclone Liner Mechanical and Chemical Cleaning services ensure optimal functionality, extended equipment lifespan, and reduced downtime.

Our Process:

- Liner Removal from Hydro Cyclone Vessel

Our expert technicians carefully remove the liners from the hydro cyclone vessel, ensuring minimal disruption to operations. - Chemical Cleaning

We utilize industry-approved chemical cleaning methods to dissolve stubborn deposits, scaling, and contaminants without damaging the liner material. - Mechanical Cleaning

For tougher residues, we employ precision mechanical cleaning techniques, restoring the liners to their optimal condition. - Visual Inspection

A thorough inspection is conducted to assess liner integrity, identifying any signs of wear, damage, or potential failure points. - Re-installation

Once cleaned and inspected, the liners are carefully re-installed to ensure seamless performance and extended operational efficiency.

Contact Person

Noel Menezes

Associate Manager - Sales ICML – VPR Certified

Contact Person

Vanda Franco

Associate Manager – Operations (onshore)