Column, Vessel and Reactor Internals – Process and Chemicals 2025

Column, Vessel and Reactor Internals

We provide high-performance Column, Vessel, and Reactor Internals essential to efficient oil and gas processing. These components are critical for optimizing separation, reaction, and flow dynamics. Our tailored solutions also support debottlenecking operations, enhancing capacity, reliability, and performance to meet the evolving demands of today’s energy industry.

Petrotec is the authorized representative of Koch Glitsch and Johnson Screens in Qatar.

Key Benefits

-

Improved Process Efficiency

Optimizes mass transfer and separation processes, leading to higher yields and better product quality in chemical, petrochemical, and pharmaceutical industries.

-

Customization

Tailors internals to meet the unique needs of various processes, including distillation, absorption, stripping, and catalytic reactions maximizing cost savings and debottlenecking as required.

-

Local Support

Petrotec offers tailored technical support and on ground expertise in Qatar. Our deep understanding and expertise in the local market allows for rapid response times and customized solutions that address the unique challenges faced by Qatar's energy industry.

Key Products

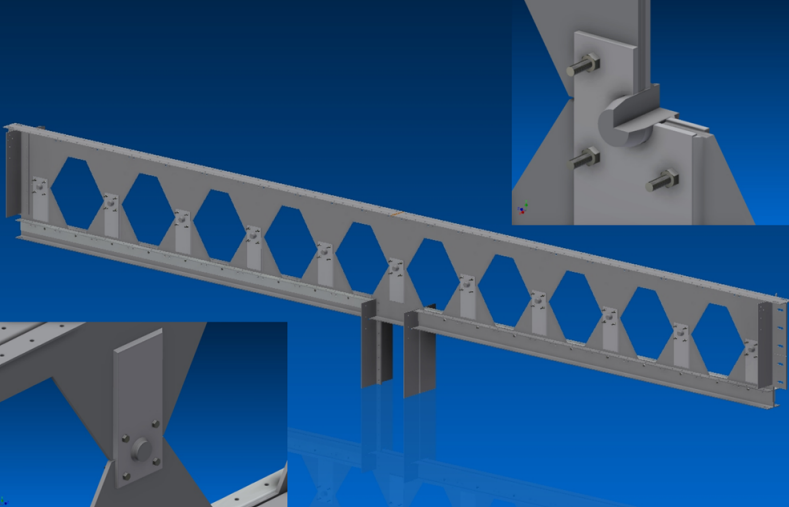

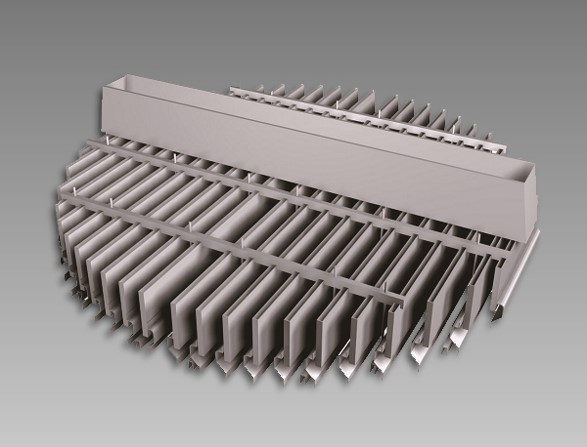

Trays

Column and vessel internal trays are critical components in mass transfer operations within the oil and gas industry. These trays significantly enhance the efficiency of separation processes in distillation, absorption, and stripping applications—core operations in refining and petrochemical plants. As a global leader in mass transfer technology, Koch Glitsch delivers innovative and high-performance internal solutions that ensure optimal productivity and reliability across diverse processing environments.

In Qatar, where the energy sector plays a pivotal role in the national economy, the performance and longevity of such equipment are essential. Here, Petrotec plays a key role as Koch Glitsch’s exclusive local partner, bringing unmatched value through deep market intelligence, prompt technical support, and access to skilled local manpower. Petrotec bridges the global excellence of Koch Glitsch with the specific needs of Qatar’s industrial landscape, ensuring that customers benefit from world-class solutions tailored for regional conditions.

Together, Koch Glitsch and Petrotec are driving efficiency, safety, and innovation in Qatar’s Oil and Gas processing facilities—supporting the country’s strategic goals in energy production and export.

Packing

Column and vessel internal packing plays a crucial role in mass transfer operations across the oil and gas industry, particularly in processes such as distillation, absorption, and stripping. These internals are designed to promote efficient contact between liquid and vapor phases, directly impacting throughput, pressure drop, and product purity. Koch Glitsch, a global leader in mass transfer technology, offers a wide range of high-performance packings—including structured packing (e.g., FLEXIPAC®, INTALOX® Structured Packing) and random packing (e.g., INTALOX® Saddles, IMTP® Packing)—engineered to optimize efficiency and reduce operational costs.

In Qatar, where large-scale gas processing and petrochemical operations demand world-class performance, the right packing technology is essential. Petrotec, Koch Glitsch’s trusted local partner, ensures these solutions are seamlessly integrated into the local market. With in-depth market intelligence, responsive technical support, and access to qualified local manpower, Petrotec adds significant value by aligning global innovation with Qatar’s unique industry needs.

Together, Koch Glitsch and Petrotec provide unmatched support for the region’s energy infrastructure, reinforcing Qatar’s position as a leader in the global energy sector.

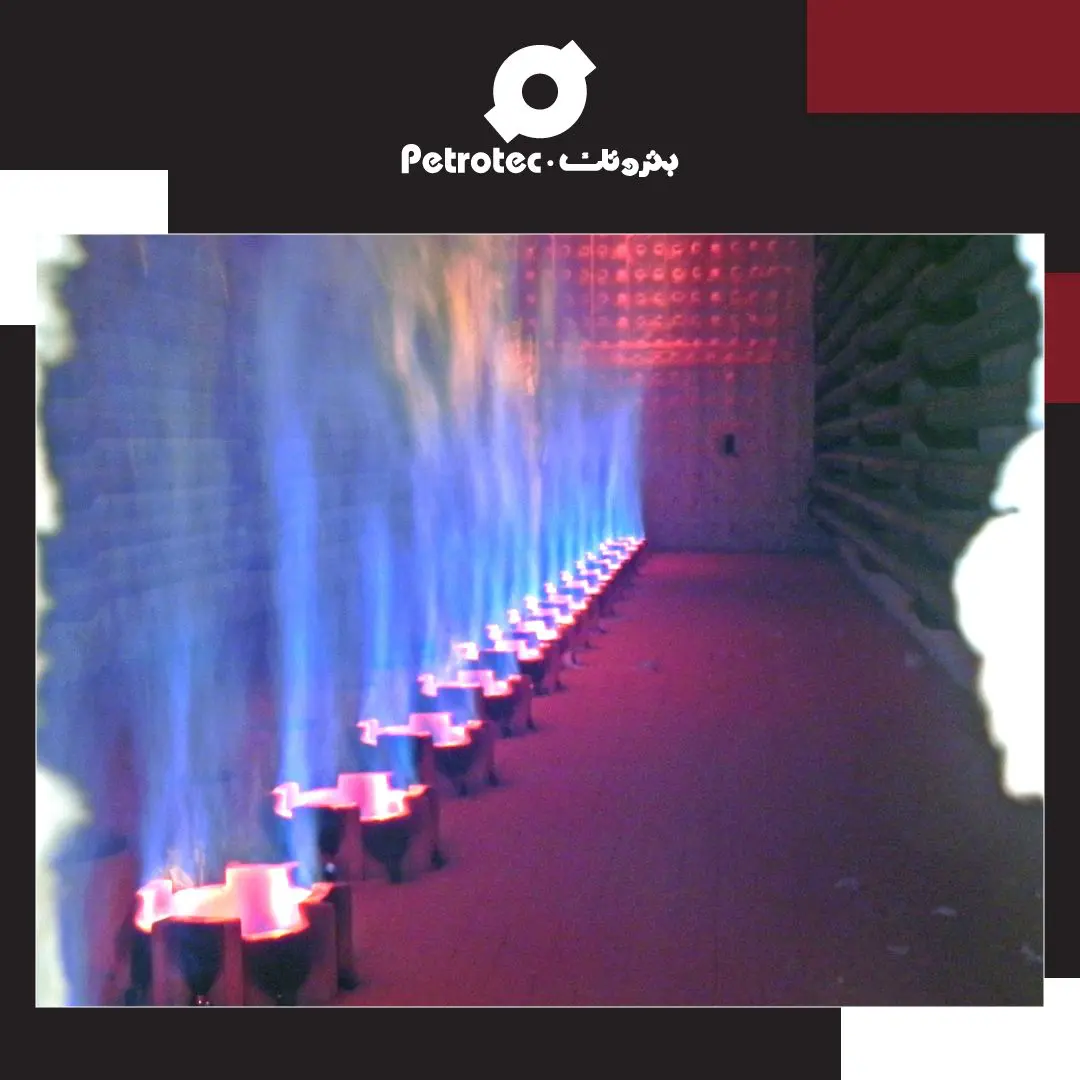

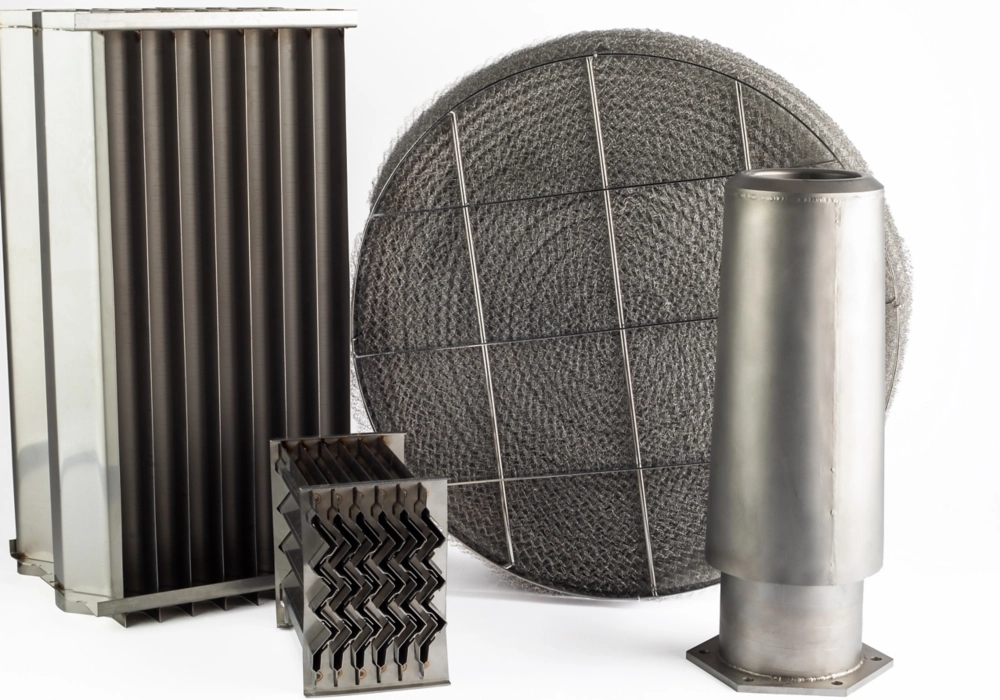

Demisters

In the Oil and Gas industry, efficient mass transfer is fundamental to optimizing productivity, ensuring safety, and minimizing environmental impact. Demister mist eliminators from global leader Koch-Glitsch are essential components in this process, effectively removing entrained liquid droplets from vapor streams to protect downstream equipment and improve separation efficiency.

Koch-Glitsch offers a comprehensive portfolio of high-performance mist elimination solutions, including KOCH-OTM® Mesh Pads, HiCap®, FlexiFlow®, and Koch-Otto York™ vane-type mist eliminators. These technologies are designed to deliver maximum throughput, minimal pressure drop, and long service life—making them indispensable in demanding applications across the oil and gas sector.

In Qatar, Koch-Glitsch’s strategic partnership with Petrotec ensures seamless local support. As the exclusive partner, Petrotec brings unmatched market intelligence, access to skilled local manpower, and responsive technical assistance, enhancing the value and effectiveness of Koch-Glitsch solutions within Qatar’s dynamic energy landscape.

Together, Koch-Glitsch and Petrotec empower Qatari Oil and Gas operations with world-class mist elimination technology and reliable local execution for long-term performance and efficiency.

Flow Distributors

Flow distributors play a critical role in optimizing column internals for oil and gas processing, ensuring uniform fluid distribution and maximizing separation efficiency. As a global leader in mass transfer technology, Koch-Glitsch has consistently advanced the design and performance of flow distributors to meet the evolving demands of the industry. Their innovative solutions have enhanced operational reliability and throughput in complex process environments. In Qatar, Petrotec has been instrumental in supporting Koch-Glitsch’s presence, acting as a key partner in delivering localized expertise, technical support, and seamless project execution. Through this collaboration, Petrotec and Koch-Glitsch continue to provide cutting-edge solutions tailored to the unique challenges of the region’s Oil and Gas sector.

Reactor Internals

In high performance refining and petrochemical operations, Johnson Screens, a global leader in filtration and separation solutions, offers a comprehensive range of reactor internals tailored for radial, downward, and upward flow applications. Their advanced designs, including scallops and precision-engineered components, optimize flow distribution and mechanical stability across diverse process requirements.

For radial flow reactors, Johnson Screens internals ensure uniform fluid distribution, reducing maldistribution and enhancing process consistency. In downward flow systems, their internals facilitate controlled liquid movement, minimizing channeling and pressure drop. Meanwhile, upward flow applications benefit from internals designed to support gas-liquid interactions while maintaining structural integrity under challenging conditions.

A key feature of Johnson Screens’ internals is the V-shaped profile, which improves mechanical strength and fluid flow management. This profile enhances liquid distribution and solids handling, reduces clogging risk, and extends equipment lifespan—critical advantages in high-demand hydrocarbon processing environments.

In Qatar, Johnson Screens’ capabilities are strengthened by their local partner Petrotec, which provides essential market intelligence and tailored technical support, ensuring seamless integration and optimal performance of these reactor internals within the region’s complex operational landscape.

Together, they deliver innovative solutions that drive efficiency, reliability, and cost-effectiveness for Qatar’s Oil and Gas operators.

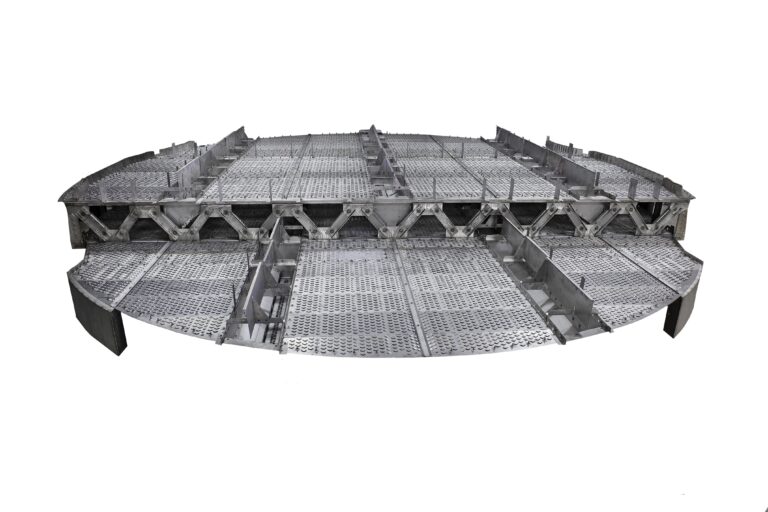

Support Grids

Johnson Screens is a global leader in advanced reactor internals, offering a broad portfolio of support grids designed to provide exceptional catalyst support and facilitate a range of critical applications within the oil and gas industry. These support grids are engineered to deliver robust mechanical strength, uniform catalyst distribution, and optimized flow dynamics—vital for maximizing reactor efficiency and longevity.

Johnson Screens’ support grids are tailored for applications including:

- Catalyst support: Providing a stable bed for catalysts while minimizing pressure drop and preventing catalyst attrition.

- Particle retention: Ensuring effective containment of catalyst or packing materials within reactor beds.

- Bed support in hydroprocessing: Enhancing performance in hydrotreating and hydrocracking reactors.

- Demister and distributor support: Assisting in the effective separation of liquid droplets and even distribution of process fluids.

The grids incorporate innovative design features such as the V-shaped profile, which enhances mechanical rigidity and improves fluid flow uniformity—reducing fouling and extending operational cycles under demanding process conditions.

In Qatar, Johnson Screens’ offerings are complemented by Petrotec, the trusted local partner providing vital market insights and technical expertise to ensure seamless implementation and optimized performance tailored to the region’s unique operational challenges.

Together, Johnson Screens and Petrotec deliver engineered support grid solutions that drive operational excellence and cost efficiency for Qatar’s Oil and Gas industry.

Mechanical Supports

Koch-Glitsch offers industry-leading mechanical support solutions, including their trademarked Omni-Fit™ and Omni-Tie™ systems, designed to simplify the installation of vessels and columns in hydrocarbon processing plants. These supports ensure optimal structural alignment and stability, allowing operators to avoid costly and time-consuming hydrotesting of vessels and columns. Eliminating or minimizing hydrotesting accelerates project timelines, reduces operational risks, and lowers overall costs.

In Qatar’s dynamic hydrocarbon sector, Koch-Glitsch’s advanced mechanical supports provide reliable, efficient installation tailored to the region’s challenging conditions. Their innovative designs deliver precise fit and robust performance, ensuring long-term operational integrity and seamless project execution.

Key to this success is Petrotec, Koch-Glitsch’s trusted local partner in Qatar. Petrotec brings invaluable market intelligence and a skilled local workforce, facilitating smooth coordination, compliance with regional regulations, and timely delivery. This collaboration guarantees customers comprehensive support, combining Koch-Glitsch’s cutting-edge technology with Petrotec’s deep local expertise, enabling efficient, risk-mitigated installations and faster project completion in Qatar’s hydrocarbon processing industry.