Customized Process Packages & Specialty Chemicals- Process and Chemicals 2025 – Copy

Customized Process Packages & Specialty Chemicals

Custom process skids are engineered modular systems that integrate components like pumps, valves, instrumentation, and control panels onto a single frame. These pre-assembled units streamline installation, reduce on-site labor, and enhance operational efficiency across industries such as oil & gas, water treatment, and chemical processing

Opting for reliable partners in critical process needs is paramount. Collaborating with experienced manufacturers ensures compliance with industry standards, reduces risks, and enhances system performance and safety.

Petrotec is the authorized representative of Villa Scambiatori, ProSep, Lewa and Eta Process Plant in Qatar.

Key Benefits

-

Optimized System Integration

Custom packages ensure seamless integration with existing infrastructure, reducing potential compatibility issues and improving overall system performance.

-

Innovative Technology

Our custom packages allow for the integration of cutting-edge technologies (e.g., AI, automation, advanced sensors), keeping the energy system competitive and efficient.

-

Local Support

Petrotec offers tailored technical support and on ground expertise in Qatar. Our deep understanding and expertise in the local market allows for rapid response times and customized solutions that address the unique challenges faced by Qatar's energy industry.

Key Products

Acid Gas Removal Units

We provide state-of-the-art acid gas removal systems, essential for the oil and gas industry, particularly in Qatar. Acid gas removal involves the extraction of hazardous gases such as hydrogen sulfide (H₂S) and carbon dioxide (CO₂) from natural gas and refinery streams. This process is vital to meet environmental regulations, ensure safe operations, and protect infrastructure from corrosion. Our solutions deliver high efficiency, reliability, and environmental compliance, making them well-suited for the demanding conditions of Qatar’s energy sector.

A critical factor in the Qatari market is partnership with Petrotec, a trusted local collaborator. Petrotec’s deep understanding of the local market dynamics, regulatory environment, and operational challenges adds significant value by offering targeted market intelligence and practical local expertise. The partnership to tailor its acid gas removal technologies effectively, ensuring smooth project execution and optimal system performance. Petrotec provides Qatar’s oil and gas operators with innovative, sustainable, and efficient solutions that support the country’s energy ambitions.

Mercaptan Removal & Dehydration

We deliver advanced dehydration and mercaptan removal packages designed to meet the stringent requirements of the oil and gas industry, with a strong focus on performance, safety, and regulatory compliance. Dehydration systems remove water vapor from natural gas to prevent hydrate formation and corrosion, thereby ensuring gas quality and protecting downstream infrastructure. Mercaptan removal systems eliminate sulfur-containing compounds that contribute to odor, corrosion, and environmental challenges, enabling producers to meet product specifications and emissions standards.

A critical factor in the Qatari market is partnership with Petrotec, a trusted local collaborator. Petrotec’s deep understanding of the local market dynamics, regulatory environment, and operational challenges adds significant value by offering targeted market intelligence and practical local expertise. The partnership to tailor its acid gas removal technologies effectively, ensuring smooth project execution and optimal system performance. Petrotec provides Qatar’s oil and gas operators with innovative, sustainable, and efficient solutions that support the country’s energy ambitions.

Produced Water Systems – Hydrocyclones, Induced Gas Floatation & Polishing

We deliver fully integrated produced water treatment systems, designed to address one of the most complex environmental challenges in hydrocarbon production. Produced water, often laden with hydrocarbons, suspended solids, and dissolved contaminants, must be carefully treated to meet stringent discharge or reinjection standards. Our approach encompasses all critical stages – bulk separation, deoiling, fine filtration, and polishing – ensuring reliable performance under varying operating conditions.

In Qatar, where environmental compliance and resource optimization are of strategic importance, effective produced water management is not just a regulatory requirement, it is an operational imperative. A critical factor in the Qatari market is partnership with Petrotec, a trusted local collaborator. Petrotec’s deep understanding of the local market dynamics, regulatory environment, and operational challenges adds significant value by offering targeted market intelligence and practical local expertise. The partnership to tailor its acid gas removal technologies effectively, ensuring smooth project execution and optimal system performance. Petrotec provides Qatar’s oil and gas operators with innovative, sustainable, and efficient solutions that support the country’s energy ambitions.

Dew Point Control

In the oil and gas industry, managing hydrocarbon and water dew points is critical to ensure safe and efficient gas processing and transportation. We offer advanced dew point control technologies designed to meet the stringent specifications required by gas processing facilities across the Middle East. These solutions help prevent condensation in pipelines and equipment, mitigating corrosion, hydrate formation, and operational downtime.

In Qatar, a key market for energy production and export, we work closely with end users. A critical factor in the Qatari market is partnership with Petrotec, a trusted local collaborator. Petrotec’s deep understanding of the local market dynamics, regulatory environment, and operational challenges adds significant value by offering targeted market intelligence and practical local expertise. The partnership to tailor its acid gas removal technologies effectively, ensuring smooth project execution and optimal system performance. Petrotec provides Qatar’s oil and gas operators with innovative, sustainable, and efficient solutions that support the country’s energy ambitions.

Fuel & Seal Gas Conditioning

In the hydrocarbon industry, the conditioning of fuel gas and seal gas is critical to ensuring reliable and efficient operation of rotating equipment such as turbines and compressors. Fuel gas conditioning involves removing contaminants, moisture, and particulates to protect combustion systems and maintain optimal performance. Similarly, seal gas conditioning is essential for centrifugal compressors, where clean, dry gas prevents leakage and protects sensitive components from wear and contamination.

Petrotec, a leading provider of energy services in Qatar, plays a key role in supporting these vital processes. Through its partnerships with globally recognized OEMs and technology providers, Petrotec delivers advanced conditioning systems designed for the harsh operating environments of the Gulf region. Their solutions help ensure compliance with stringent process requirements while minimizing downtime and enhancing operational safety.

With its strong local presence and technical expertise, Petrotec continues to contribute to the reliability and efficiency of Qatar’s hydrocarbon infrastructure by offering tailored support and solutions for both fuel and seal gas conditioning systems.

Crude Desalters

Crude desalters are critical units in the oil refining process, designed to remove salts, water, and other impurities from crude oil before it enters downstream processing. These impurities, if untreated, can cause corrosion, fouling, and catalyst deactivation in refinery equipment.

A critical factor in the Qatari market is partnership with Petrotec, a trusted local collaborator. Petrotec’s deep understanding of the local market dynamics, regulatory environment, and operational challenges adds significant value by offering targeted market intelligence and practical local expertise. The partnership to tailor its acid gas removal technologies effectively, ensuring smooth project execution and optimal system performance. Petrotec provides Qatar’s oil and gas operators with innovative, sustainable, and efficient solutions that support the country’s energy ambitions.

Columns & Reactors

Columns and reactors are essential components in chemical and industrial processes, playing a crucial role in separation, purification, and conversion of various streams to end products. These specialized units are designed to meet specific process requirements, enabling enhanced efficiency, selectivity, and yield in diverse applications across industries such as chemicals, fertilizers, energy, etc. Villa Scambiatori has long-standing expertise in the design and manufacturing of columns and reactors for continuous or batch system liquid-liquid separation processes. With their advanced in-house design and fabrication capabilities, they can make customized columns and reactors adhering to international standards. Proficiency lies in the fabrication of equipment for high-pressure and high-temperature applications, utilizing high-grade exotic alloys such as titanium, incoloy, duplex, super duplex etc.

Proprietary High Energy Mixers

ProSep’s High-Efficiency Mixers use their advanced proprietary design engineered to utilize fluid dynamics mechanisms that break down mixing barriers and ensure comprehensive fluid contact, surpassing conventional mixing methods.

Key Advantages offered by ProSeps High –Efficiency mixers include:

- Precision Mixing: ProSep’s mixers offer exceptional homogeneity and consistency, guaranteeing uniform and accurate blending of even the most complex fluids.

- Enhanced Reaction Rates: The mixers accelerate reaction kinetics, reducing processing time and enabling higher throughput, resulting in boosted productivity and reduced operational costs.

- Minimal Energy and material Consumption: With their innovative design, ProSep mixers minimize energy and material consumption without compromising on performance.

- Versatile Applicability: Whether in the oil and gas, chemical, pharmaceutical, or water treatment industries, ProSep mixers cater to a wide spectrum of applications, accommodating diverse fluid properties and process conditions.

- Reliable Scalability: ProSep’s mixers are designed to adapt seamlessly to varying process scales. From lab-scale trials to large-scale production, our mixers consistently deliver optimized results.

- Intelligent Process Control: ProSep mixers can be integrated with advanced process control systems, enabling real-time monitoring and adjustment, further enhancing efficiency and performance.

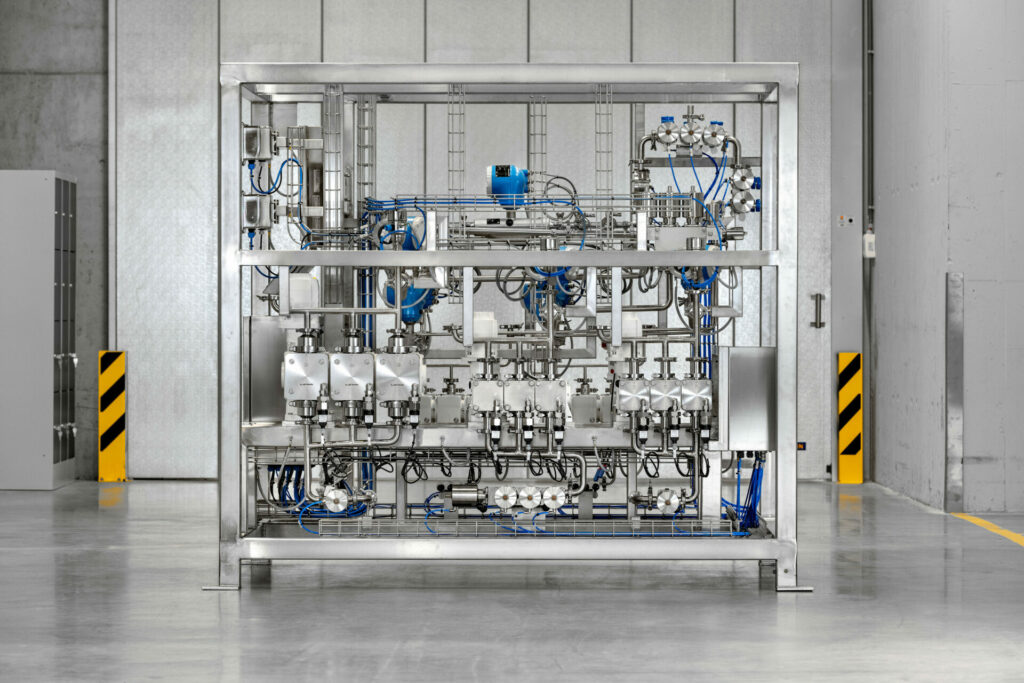

Chemical Injection Packages

Chemical Injection is a key activity in all Energy industries which requires complex systems to ensure precise and accurate dosing of a wide range of dosing fluids into sensitive processes. LEWA has over 60 years of industry experience in the design and fabrication of custom chemical injection packages for both offshore and onshore applications, tailored to customer requirements, and complying with both with industry specifications and international standards (such as ASME, API, and ATEX). Boasting a wide range of precision dosing pumps in plunger and diaphragm configurations, LEWA can provide a highly reliable injection package including all associated auxiliary instruments and motors with different drive types, flexible construction of storage tanks, pressure-dependent piping, and using high-alloy construction materials.

Petrotec being the authorized distributor and service provider for LEWA in Qatar, provides extensive local support with the refurbishment of LEWA Chemical Injection Skids and Pumps, and are also a LEWA partner for the assembly of skids in Qatar. Our dedicated facility in Ras Laffan has trained personnel for these activities and we have extensive references for repair and refurbishment of injection packages installed both onshore and offshore.

Odorizing Systems

LEWA odorizing systems are vital for adding odorants such as mercaptans to odourless gases, ensuring gas leak detection and public safety. These systems find application in gas distribution, refining and chemical processing.

Key features include precise technology like diaphragm and metering pumps, alongside electronic control units for optimal odorant-to-gas ratios. Metering pumps provide consistent injection rates across a wide range of odorants and gases, while electronic units enable remote monitoring and data logging.

Safety is prioritized through adherence to industry regulations, preventing over- or under-odorization that could lead to false alarms or undetected leaks. Customization options cater to specific gas types, flow rates, and conditions, allowing seamless integration into existing infrastructure.

LEWA odorizing systems effectively enhance safety by adding distinct odors to gases, enabling timely leak detection and safeguarding the environment, public health, and industrial facilities. With a focus on accuracy, compliance, and adaptability, LEWA odorizing systems stand as trusted solutions for efficient and reliable gas odorization.

Customized Metering Systems

LEWA metering systems offer advanced solutions for precise fluid dosing in industries like chemicals, pharmaceuticals, oil and gas, and food production for metering, heating cooling and regulating applications.. These systems employ cutting-edge technology, featuring plunger and diaphragm pumps alongside electronic control units and other instrumentation and auxiliary devices.

The core strength of LEWA systems lies in their metering pumps, delivering exceptional accuracy and repeatability across various fluid types and conditions. This versatility ensures suitability for a wide range of applications.

Safety and compliance are central to LEWA metering systems. The systems maintain strict dosing accuracy, crucial for product quality and regulatory adherence. Real-time monitoring and adjustments through electronic control units further enhance dosing control.

LEWA metering systems are designed for customization, catering to diverse flow rates, pressures, and fluid properties. Their seamless integration into existing processes supports retrofitting and new installations alike.

In conclusion, LEWA metering systems stand as advanced solutions for precise fluid dosing. With their sophisticated metering pumps, engineered components, and electronic controls, these systems elevate product quality, process efficiency, and safety standards. Known for accuracy, adaptability, and regulatory compliance, LEWA metering systems effectively address the intricate dosing requirements of modern industries.

Dosing Flow Distribution Systems

For many complex Energy processes, there are instances when chemical injection is required at multiple separate points using the same process fluid. This can be a challenge due to the requirement of multiple pumps and extended pipelines and auxiliary devices. For such cases, LEWA offers custom-designed Flow Distribution systems along with Injection Rate Control Devices, which can be utilized for metered dosing of process fluid to achieve multi-point injection using only one high-pressure pipeline. This system provides a highly optimized solution in terms of both space as well as cost since you eliminate the need for multiple pumps, motors and pipelines. Moreover, it also offers the flexibility to extend the number of injection points and add additional auxiliary devices as necessary.

Bespoke Process Packages

Petrotec is fully equipped to provide comprehensive support for all types of custom process packages tailored to the Qatari energy sector. Leveraging extensive industry expertise and a thorough understanding of regional standards and regulations, Petrotec delivers end-to-end solutions encompassing design, engineering, fabrication, and commissioning. Our commitment to excellence ensures seamless integration with existing infrastructure across upstream, midstream, and downstream operations. By maintaining rigorous quality control and adhering to international best practices, Petrotec consistently drives operational efficiency and reliability, positioning itself as a trusted partner in advancing Qatar’s energy industry.

Specialty Chemicals

Petrotec is pleased to offer a wide range of specialty chemicals for Qatar’s energy sector, supporting upstream, midstream, and downstream operations. Our solutions are backed by technical expertise and reliable local supply to enhance performance, safety, and operational efficiency across the industry.