Emission Control Solutions and Combustion- Process and Chemicals 2025

Emission Control Solutions and Combustion

We provide advanced Emission Control Solutions and Combustion technologies to support cleaner, more efficient energy operations. In line with Qatar’s Vision 2030, our solutions help reduce emissions and optimize performance, contributing to a sustainable, low-carbon future while supporting the nation’s goals for environmental protection and responsible industrial development.

Petrotec is the authorized representative of John Zink, BASF, GRACE, and Babcock & Wilcox in Qatar

Key Benefits

-

Regulatory Incentives for End Users

Our emission control solutions can support End Users to tap into government incentives, subsidies and applicable benefits for environmentally responsible practices.

-

Sustainable Growth

Aligns with growing global demand for sustainable and green technologies, positioning our End Users as leaders in the clean tech sector.

-

Local Support

Petrotec offers tailored technical support and on ground expertise in Qatar. Our deep understanding and expertise in the local market allows for rapid response times and customized solutions that address the unique challenges faced by Qatar's energy industry.

Key Products

Process Burner Packages

Process Burner Packages are vital to the Energy industry, enabling safe, efficient combustion in critical refining and petrochemical operations. As a global leader in emissions control and heat transfer technology, John Zink offers state-of-the-art Process Burner Packages that meet the highest standards of safety, operational reliability, and environmental compliance.

In alignment with Qatar National Vision 2030, which emphasizes sustainable development and environmental protection, John Zink’s advanced burner technologies – particularly DeNOx burners – play a crucial role in helping operators reduce harmful nitrogen oxide (NOx) emissions. These systems support the energy sector’s transition to more environmentally responsible operations, contributing to cleaner air and improved public health.

In Qatar, where the energy sector continues to drive national growth, the deployment of DeNOx-equipped Process Burner Packages ensures optimal performance while supporting the country’s long-term environmental goals.

Petrotec, John Zink’s exclusive local partner, adds significant value through deep local market knowledge, technical expertise, and a skilled workforce. Their strong presence across Qatar enables rapid response, customized support, and seamless system integration tailored to regional operational demands.

Together, John Zink and Petrotec deliver a powerful combination of global innovation and localized service—empowering Qatar’s oil and gas operators with combustion solutions that advance safety, enhance efficiency, and align with the country’s commitment to a sustainable future under Qatar Vision 2030.

Boiler Burner Packages

Boiler Burner Packages are a critical component in the process industry, ensuring efficient and environmentally compliant combustion processes essential for upstream and downstream operations. John Zink, a global leader in advanced combustion technologies, offers high-performance Boiler Burner Packages designed to meet the demanding standards of the energy sector. These systems not only enhance operational efficiency but also reduce emissions, aligning with Qatar’s commitment to sustainability and industrial excellence.

In Qatar, Petrotec stands as John Zink’s trusted local partner, delivering unmatched value through deep market knowledge and strategic support. With a strong understanding of regulatory frameworks and operational requirements, Petrotec bridges the gap between international innovation and local execution. The company’s ability to provide skilled local manpower, rapid technical assistance, and real-time market intelligence ensures smooth project execution and lifecycle support. Together, John Zink and Petrotec empower Qatar’s energy sector with world-class combustion solutions, tailored for local success.

Flare Packages

Flare Packages play a vital safety and environmental role in the oil and gas processing industry, managing excess gases through controlled combustion. John Zink, a globally recognized name in flare technology, delivers highly engineered solutions tailored for performance, reliability, and regulatory compliance. Their comprehensive range includes elevated flares, ground flares, enclosed flares, and offshore flare systems – each designed to handle varying flow rates, compositions, and site constraints while minimizing noise, smoke, and emissions.

In Qatar, where environmental performance and operational safety are paramount, John Zink’s flare solutions are particularly relevant. Supporting these efforts on the ground is Petrotec, John Zink’s exclusive partner in the country. Petrotec brings critical local value by offering market insight, ensuring alignment with national regulations, and deploying qualified local manpower to manage installation, commissioning, and after-sales support. This partnership ensures clients benefit from world-class flare systems backed by responsive, in-country expertise. Together, John Zink and Petrotec enable safer, cleaner, and more efficient flaring operations that meet the evolving needs of Qatar’s energy sector.

Flare Gas Recovery Package

The Flare Gas Recovery Package offered by John Zink is a vital solution for the oil and gas industry, especially in environmentally conscious regions like Qatar. As part of Qatar National Vision 2030, the country is committed to sustainable development and stringent environmental regulations. The recovery of flare gas—typically wasted during production—helps reduce greenhouse gas emissions, enhances energy efficiency, and supports cleaner operations. John Zink’s advanced technology enables operators to capture and reuse flare gas, aligning perfectly with national sustainability goals.

In Qatar, the value of this package is further enhanced through John Zink’s partnership with Petrotec, a trusted local partner with deep-rooted expertise in the energy sector. Petrotec provides critical market intelligence, navigates local regulatory frameworks, and supplies skilled local manpower, ensuring seamless implementation and ongoing support. This collaboration not only accelerates environmental compliance but also promotes knowledge transfer and capacity building within the local workforce, reinforcing the broader objectives of Vision 2030.

Thermal Oxidizer Package

John Zink’s Thermal Oxidizer Package plays a critical role in ensuring safe and environmentally responsible operations in the oil and gas industry. Designed to treat and destroy hazardous hydrocarbons and volatile organic compounds (VOCs), this system helps operators meet strict emission control standards while improving operational safety and environmental performance. In a country like Qatar, where environmental sustainability is a national priority under Qatar Vision 2030, the deployment of reliable emission control technologies is more essential than ever.

John Zink’s proven expertise in combustion and emission control is effectively complemented by Petrotec, its exclusive local partner in Qatar. Petrotec adds substantial value by offering in-depth market intelligence, regulatory insight, and strong local support throughout the project lifecycle.

From pre-sales consultation to after-sales service, Petrotec ensures that John Zink’s Thermal Oxidizer solutions are tailored to the unique needs of the Qatari market. Additionally, Petrotec’s commitment to employing and training local manpower supports Qatar’s localization and workforce development goals, making this partnership a model of sustainable and effective technology deployment.

Vapor Recovery Units

John Zink’s Vapor Recovery Unit (VRU) is an essential technology for reducing emissions and capturing valuable hydrocarbons in oil and gas operations. By recovering vapors that would otherwise be flared or vented, the VRU not only minimizes environmental impact but also enhances operational efficiency and resource utilization. In Qatar—where environmental stewardship is a cornerstone of Qatar National Vision 2030—deploying advanced vapor recovery systems is a strategic imperative for operators aiming to align with evolving regulatory expectations and sustainability targets.

The success of John Zink’s VRU solutions in Qatar is further strengthened by its partnership with Petrotec. As a leading local provider of industrial solutions, Petrotec brings critical insight into the Qatari market landscape. Their on-ground presence ensures agile response times, effective regulatory navigation, and comprehensive support across installation, commissioning, and maintenance phases. Petrotec also plays a pivotal role in driving localization by leveraging skilled Qatari talent and delivering customized solutions that reflect local operating conditions. Together, John Zink and Petrotec enable clients in Qatar to adopt environmentally responsible technologies without compromising on performance or reliability.

Flue Gas Treatment

Babcock & Wilcox (B&W), a global leader in clean energy and environmental technologies, offers a comprehensive suite of emission control equipment designed to reduce SOx, NOx, particulate matter, and mercury from flue gases in fossil fuel and biomass-fired steam generators and industrial processes. Our proven technologies include flue gas desulfurization (wet, spray dry, and circulating dry), electrostatic precipitators (wet and dry), fabric filters, dry sorbent injection, and selective catalytic reduction (SCR) systems. These systems are supported by advanced emissions monitoring and ash management solutions to ensure compliance with the most stringent environmental standards.

In Qatar, B&W proudly partners with Petrotec to provide local expertise, technical support, and project execution tailored to the region’s energy and industrial needs. Together, we deliver turnkey solutions, from design and engineering to installation and after-sales service, ensuring high system performance and long-term reliability. Our partnership with Petrotec reinforces our commitment to environmental stewardship and sustainable development in Qatar, offering cutting-edge emissions control technologies backed by robust local support. B&W and Petrotec are ready to support Qatar’s drive toward cleaner, more efficient industrial operations through world-class flue gas treatment systems.

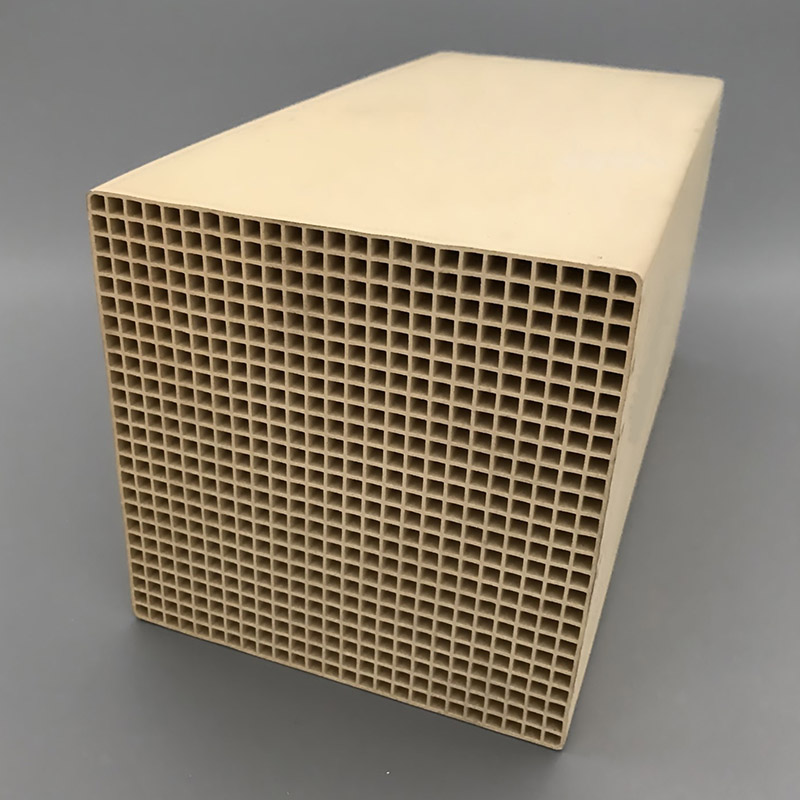

DeNOx Catalyst

BASF’s DeNOx honeycomb catalysts play a crucial role in reducing nitrogen oxide (NOx) emissions from industrial processes, particularly in the petrochemical sector. These catalysts are designed for high efficiency and durability, making them essential for meeting stringent environmental regulations. In Qatar, where the petrochemical industry is a significant part of the economy, the demand for advanced emission control technologies is ever-increasing.

Petrotec has been a key partner in promoting and implementing BASF’s DeNOx solutions in Qatar. With its deep understanding of the local market and strong relationships with industry stakeholders, Petrotec has facilitated the adoption of these cutting-edge catalysts. By providing tailored solutions that meet the specific needs of Qatari facilities, Petrotec has helped optimize the performance of BASF’s catalysts, ensuring compliance with both local and international emissions standards.

The collaboration between BASF and Petrotec not only enhances operational efficiency but also contributes to Qatar’s commitment to sustainable development. As the nation continues to expand its petrochemical capacity, the partnership stands as a testament to the effectiveness of innovative technology in addressing environmental challenges while supporting industrial growth. Together, they are paving the way for a cleaner, more sustainable future in Qatar’s petrochemical landscape.

DeSOx Catalyst

DeSOx catalysts from Grace are engineered to deliver exceptional performance in reducing sulfur emissions from industrial processes, ensuring compliance with stringent environmental regulations. These catalysts utilize advanced formulations that enhance the efficiency of desulfurization, providing a reliable solution for various applications, including oil and gas, refining, and petrochemical sectors.

In Qatar, Petrotec stands out as a key partner, offering unparalleled logistical support to ensure the seamless integration of DeSOx catalysts into operational frameworks. With a deep understanding of the local market and industry requirements, Petrotec guarantees timely delivery and comprehensive technical assistance, minimizing downtime and maximizing operational efficiency. Their expertise in navigating regional logistics challenges allows for swift mobilization of resources, ensuring that customers receive the support they need, exactly when they need it.

This synergy between Grace’s cutting-edge technology and Petrotec’s flawless local logistics empowers companies in Qatar to enhance their sustainability efforts while maintaining optimal performance. By choosing DeSOx catalysts from Grace, backed by Petrotec’s unwavering commitment to service excellence, organizations can confidently move toward a greener future, reducing their environmental footprint without compromising productivity. Together, they pave the way for a more sustainable industrial landscape in the region.

Soot Blowers

Babcock & Wilcox’s Diamond Power® soot blowers are a trusted solution for maintaining optimal heat transfer efficiency in high-performance boilers and heat exchangers—critical to the demanding operations of Qatar’s oil and gas industry. With proven technology designed to remove slag and ash buildup without interrupting system performance, these soot blowers help ensure reliability, reduce downtime, and extend equipment life in some of the region’s most challenging process environments.

In Qatar, Babcock & Wilcox strengthens its presence through a strategic partnership with Petrotec, a leading provider of industrial solutions. Petrotec enhances local value by delivering in-depth market intelligence, responsive service, and a dedicated pool of qualified manpower. This collaboration ensures rapid response times, tailored support, and compliance with Qatar’s stringent industrial and safety standards.

Together, Babcock & Wilcox and Petrotec deliver not just high-performance equipment, but also integrated support and localized expertise—enabling Qatar’s energy operators to maintain operational excellence and long-term asset integrity.

Boilers

Babcock & Wilcox (B&W) is a global leader in advanced boiler solutions, offering highly engineered boiler packages tailored for the demanding needs of the oil and gas industry. These modular systems are designed for maximum reliability, efficiency, and environmental compliance, supporting upstream, midstream, and downstream applications. In Qatar, where energy infrastructure plays a critical role in economic development, B&W’s boiler packages are an essential component of thermal process systems and power generation facilities.

Adding significant value to B&W’s presence in Qatar is Petrotec, the company’s trusted local partner. Petrotec brings deep market intelligence and a strong on-the-ground presence, ensuring that B&W’s solutions are aligned with local regulations, client expectations, and project timelines. By leveraging local manpower and engineering support, Petrotec facilitates seamless project execution, installation, and ongoing service. This partnership ensures that Qatari Oil and Gas clients receive not only world-class technology but also responsive, locally informed support tailored to the region’s specific needs.