Expansion Joints – Process and Chemicals 2025 – Copy

Expansion Joints

We supply high-quality rubber and metallic expansion joints, essential for the smooth operation of pipelines and process systems. These components absorb thermal expansion, vibration, and pressure fluctuations—protecting equipment, reducing maintenance, and ensuring process reliability. Their efficiency is critical to maintaining safe, uninterrupted flow in demanding energy and industrial environments.

Petrotec is the authorized representative of General Rubber and SFZ in Qatar.

Key Benefits

-

Thermal Expansion / Contraction Management

Expansion joints accommodate the thermal expansion and contraction of pipes, preventing damage to the system due to temperature fluctuations.

-

Vibration Dampening

They absorb vibrations from equipment like pumps, compressors, and turbines, reducing stress on the system and enhancing longevity.

-

Local Support

Petrotec offers tailored technical support and on ground expertise in Qatar. Our deep understanding and expertise in the local market allows for rapid response times and customized solutions that address the unique challenges faced by Qatar's energy industry.

Key Products

Rubber Expansion Joints

The rubber expansion joints from General Rubber are designed to absorb heavy movement from various directions, reducing noise and vibration, cycle life in tens & millions, compensating for misalignments, granting access to piping and equipment, and relieving pipe and anchor stresses. Featuring a seamless cover, hot-dip galvanized steel retaining rings, and a spool-shaped body with full rubber flanges, a leak-proof tube, multiple layers of aluminum tire cord, and high-tensile steel reinforcement, the expansion joint offers outstanding durability. As an independent expansion joint, these joints offer a cost-effective solution when integrated into rigid pipe systems with primary anchors and multiple space guides. Control units may be externally or internally attached, and are used as limit rods when there are load limitations in the structure or adjacent equipment.

General Rubber’s specially designed dismantling rubber expansion joint is designed for self-retraction to facilitate access to piping and equipment as well as for unmatched ease of installation and subsequent removal.

Expansion Joint Solar Covers

Prolonged exposure to ultraviolet radiation can significantly damage the chemical structure of rubber-bodied equipment, and can drastically reduce their lifetime and performance. General Rubber offers rubber-lined canvas and mylar-coated polyester solar covers for both existing as well as new rubber expansion joints installed in harsh conditions such as desert environments, which are lightweight and easy to install and is a relatively simple and efficient solution to ensure prolonged service life of your rubber expansion joints.

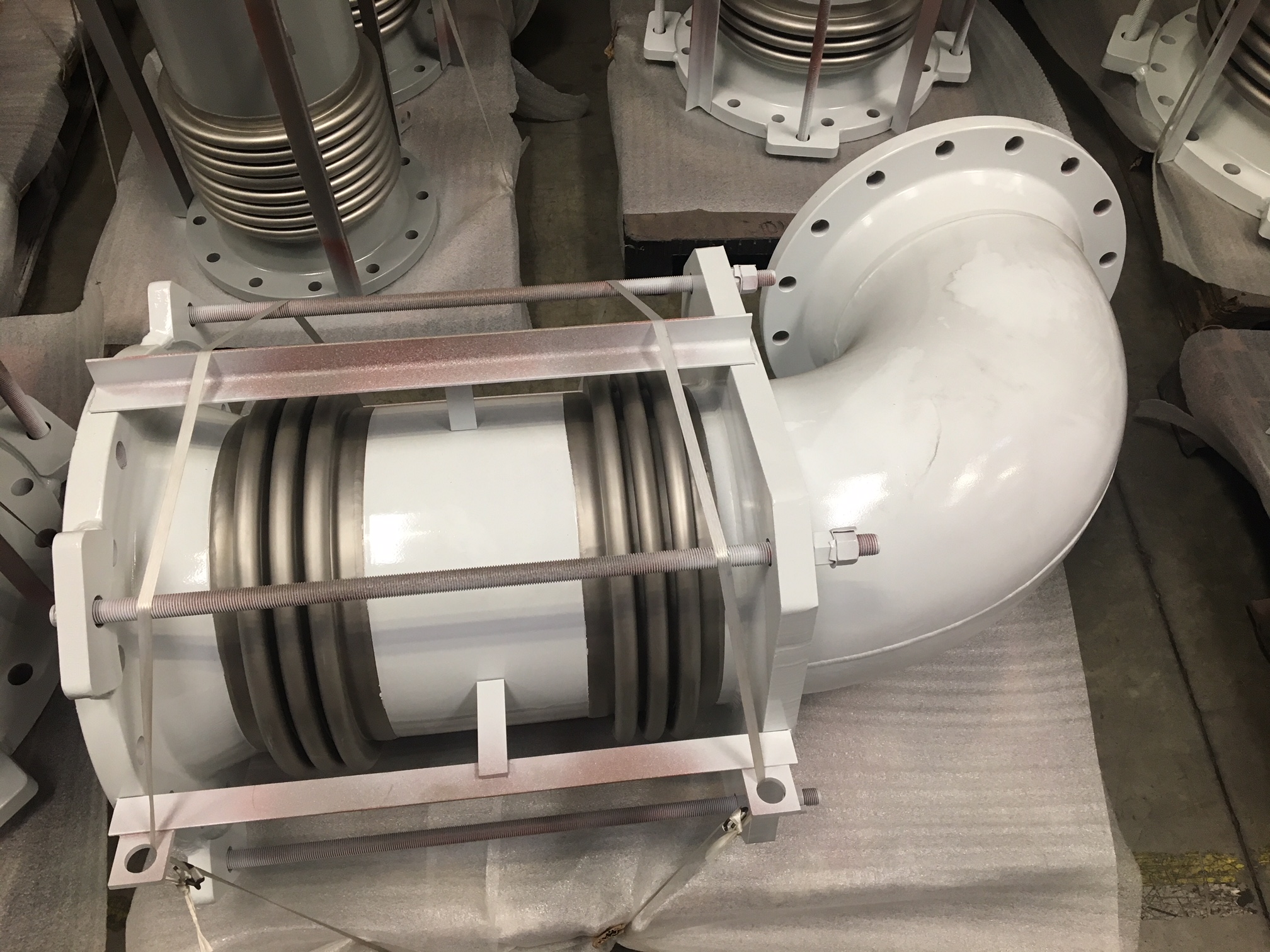

Metallic Expansion Joints

SFZ France is an expert in the design and manufacturing of Metallic expansion joints using hydroforming technique, tailored to the specifications of clients and utilising a wide array of materials such as stainless steel, nickel alloys, aluminium, duplex etc., with single or multi-layer configurations.

They are proficient in producing all types of circular expansion joints such as axial, universal, hinged, gimbal, tie-rods and pressure balanced joints, in sizes ranging from 2” to 200” and for operating temperatures of -200°C to +1200°C and operating pressures starting from vacuum to 100 Bar. The metal joints from SFZ have extensive applications and references in Refining, Petrochemicals and other Energy industries.