Heat Exchangers – Process and Chemicals 2025 – Copy

Heat Exchangers

We offer a wide range of high-quality heat exchangers in Qatar, designed to meet diverse industrial needs. Our selection includes shell and tube, plate, air-cooled, and double pipe heat exchangers, tailored for efficient thermal transfer in various applications. With a focus on durability, performance, and energy efficiency, our products are ideal for industries like Oil & Gas, petrochemical, and power generation, ensuring reliable solutions for all your heat exchange requirements.

Petrotec is the authorized representative of Metalforms, Villa Scambiatori, D'Hondt Thermal Solutions and Axial Fans Srl in Qatar.

Key Benefits

-

Improved Process Control

They enable better control of temperatures in critical processes, helping to maintain optimal operating conditions.

-

Customization

They can be tailored to meet the specific needs of different energy applications, such as Oil & Gas, geothermal, or power plants.

-

Local Support

Petrotec offers tailored technical support and on ground expertise in Qatar. Our deep understanding and expertise in the local market allows for rapid response times and customized solutions that address the unique challenges faced by Qatar's energy industry.

Key Products

Twisted Tube Heat Exchangers

The TWISTED TUBE® Heat Exchanger technology from Metalforms features a revolutionary bundle construction that incorporates a baffle-free design combined with a triangular tube pitch, resulting in compact, self-supporting tube bundles. This innovative geometry allows for a greater number of tubes within a single shell size compared to conventional bundles, increasing capacity without enlarging the equipment. The design eliminates dead spots, ensuring more efficient fluid flow and simplifying cleaning and maintenance. Additionally, the unique shroud design enables the installation of a more efficient F-type bundle inside an existing E-type shell, creating a two-pass configuration and removing the need for a full-length leaf seal, which is often prone to damage. This advancement allows users to upgrade the throughput of existing shell and tube heat exchangers without replacing the entire unit, while also offering the option for smaller, high-performance heat exchangers in new (greenfield) applications.

Hairpin Heat Exchangers

Hairpin Heat Exchangers are essential in many industries due to their efficient heat transfer facilitated by U-shaped tubes arranged in a hairpin design, enabling counterflow or parallel flow configurations.

The Metalforms BROWN FINTUBE® Hairpin Heat Exchangers offer several advantages:

- Cost-Effective: Often a single hairpin meets performance needs, reducing initial and maintenance costs compared to multiple shell-and-tube units.

- Durable in Cyclic/Shock Service: Large-radius U-bends and one-end terminal connections allow for thermal expansion without expansion joints.

- Robust Construction: Baffles welded directly to tie rods eliminate sleeves or internal nuts, enhancing strength.

- Handles Wide Temperature Differentials: Independent tube sheets and closures prevent thermal expansion issues common in conventional designs.

- High Pressure Capability: Unique closure design supports pressures over 10,000 psi.

- Easy Maintenance: Extended U-bend radius simplifies cleaning and removes the need for expansion or packed joints.

- Flexible Installation: Mobile support brackets with four-sided slots accommodate shell expansion and future upgrades without sliding plates.

- Compact Footprint: More space-efficient compared to shell-and-tube exchangers.

- Optimized for Temperature Cross: Single-pass design suits close temperature approaches and temperature cross applications.

Shell & Tube Heat Exchangers

In the Oil and Gas industry, efficient mass transfer is fundamental to optimizing productivity, ensuring safety, and minimizing environmental impact. Demister mist eliminators from global leader Koch-Glitsch are essential components in this process, effectively removing entrained liquid droplets from vapor streams to protect downstream equipment and improve separation efficiency.

Koch-Glitsch offers a comprehensive portfolio of high-performance mist elimination solutions, including KOCH-OTM® Mesh Pads, HiCap®, FlexiFlow®, and Koch-Otto York™ vane-type mist eliminators. These technologies are designed to deliver maximum throughput, minimal pressure drop, and long service life—making them indispensable in demanding applications across the oil and gas sector.

In Qatar, Koch-Glitsch’s strategic partnership with Petrotec ensures seamless local support. As the exclusive partner, Petrotec brings unmatched market intelligence, access to skilled local manpower, and responsive technical assistance, enhancing the value and effectiveness of Koch-Glitsch solutions within Qatar’s dynamic energy landscape.

Together, Koch-Glitsch and Petrotec empower Qatari Oil and Gas operations with world-class mist elimination technology and reliable local execution for long-term performance and efficiency.

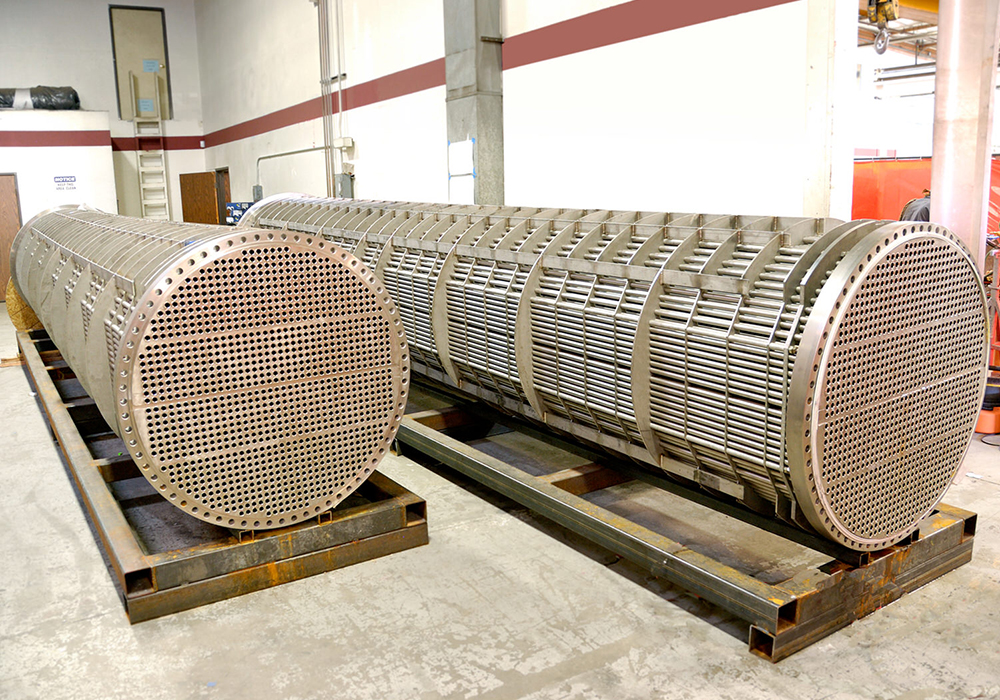

Specialty Shell & Tube Heat Exchangers

Many critical processes in the Energy and Petrochemicals industries require specialized equipment manufactured using high-grade exotic alloys and designed to withstand intense temperature and pressure conditions. Villa Scambiatori has been an industry leader in the manufacturing of specialty tube heat exchangers, having an extensive portfolio of references both onshore and offshore for design, manufacturing and supply of heat exchangers for medium/high-pressure and high temperature applications utilizing critical process fluids. With over 55 years of industry expertise, Villa Scambiatori has all the required capability and experience to manufacture and deliver equipment, starting from qualification, mechanical and thermal design, to fabrication and welding using special materials such as Titanium, Duplex and Superduplex, all carried out with stringent quality control and testing procedures.

Air Cooled Heat Exchangers

D’Hondt Thermal Solutions is a globally renowned cooling solutions partner in the Oil and Gas and Chemicals industry, and they have developed innovative technologies in the design and manufacture of high-pressure equipment for air cooling applications. Their range of API 661 finned-type air cooler units is extensively used for hydrocarbon processing, gas treatment, liquefaction and transportation. With expertise in the manufacturing of components using carbon steel, low alloy steel, stainless steel, duplex, super duplex, 254 Smo, Incoloy, titanium etc. D’Hondt has the capability to supply full air-cooled heat exchanger assemblies, as well as supply of replacement tube bundles and finned tube spares in extruded, embedded G and KLM configurations.

Tube Bundles

Frequent inspection and maintenance of your Heat Exchangers is vital to ensure continuous operation without downtime. At Petrotec, we can assist you with all your heat exchanger requirements, be it through the supply of spare tubes and bundles or with cleaning and refurbishment activities. We provide an extensive range of spares, tube and bundle replacement options for various heat exchanger types.

Axial Fans

Axial Fans Srl, based in Italy, specializes in high-efficiency axial fans tailored for demanding industrial applications, including cooling towers, heat exchangers, and HVAC systems. Their product lines, are designed to deliver optimal airflow with low noise levels, making them ideal for environments like refineries and power stations, thereby reducing carbon footprint.

In Qatar, Petrotec serves as a crucial local partner, providing engineering solutions and support to the energy sector. Collaboration with Axial Fans Srl ensures the availability of high-quality, efficient fan systems tailored to the specific needs of Qatar’s industrial landscape.

This partnership underscores the importance of local expertise in delivering reliable and efficient solutions to the energy sector in Qatar.