Process Catalysts & Adsorbents- Process and Chemicals 2025

Process Catalysts & Adsorbents

Petrotec is the authorized representative of BASF, GRACE, and Norit in Qatar

Key Benefits

-

Operational Efficiency

Our products are reliable to meet or exceed operational objectives.

-

Environmental Compliance

Our solutions are designed to meet the stringent environmental regulations.

-

Local Support

Petrotec offers tailored technical support and on ground expertise in Qatar. Our deep understanding and expertise in the local market allows for rapid response times and customized solutions that address the unique challenges faced by Qatar's energy industry.

Key Products

Claus Catalyst

Claus Catalyst is a vital component in the Claus process, an industrial method for converting hydrogen sulfide (H₂S) into elemental sulfur, essential for various industries. This catalyst, typically made from alumina and active metal oxides, facilitates the reaction between hydrogen sulfide and sulfur dioxide, significantly improving efficiency and reducing emissions in sulfur recovery units.

BASF, as a leading global chemical company, plays a crucial role in the development and supply of high-performance Claus Catalysts. Their advanced formulations enhance process effectiveness, ensuring optimal sulfur recovery rates and lower operational costs for refineries and petrochemical plants.

As BASF’s local partner in Qatar, Petrotec has been instrumental in optimizing various Claus units, leveraging their regional expertise to implement tailored solutions that enhance performance and sustainability. By collaborating closely with local stakeholders, Petrotec addresses specific operational challenges, contributing to improved efficiency in sulfur recovery.

With increasing environmental regulations and growing demand for sulfur, BASF’s expertise in catalyst technology, supported by Petrotec’s local insights, is essential for meeting both economic and sustainability goals. This partnership underscores the importance of Claus Catalysts in today’s industrial landscape, positioning Petrotec as a key player in producing cleaner, more sustainable sulfur products in Qatar.

Tail Gas Catalyst

BASF’s advanced tail gas catalyst technology plays a crucial role in optimizing industrial processes, enhancing efficiency, and reducing emissions. In the demanding environments of Qatar’s Oil and Gas sector, this innovative catalyst helps refineries and petrochemical plants meet stringent environmental regulations while improving operational performance.

Petrotec provides tailored support that is essential for maximizing the benefits of this technology. With deep market knowledge and a dedicated team, Petrotec ensures seamless integration of BASF’s tail gas catalysts into existing systems, offering on-site assistance and ongoing maintenan to guarantee optimal performance.

By leveraging BASF’s cutting-edge catalyst formulations alongside Petrotec’s localized support, customers can achieve significant reductions in harmful emissions and improve overall process efficiency.

Together, BASF and Petrotec are committed to driving sustainability in Qatar’s energy sector, ensuring that businesses can operate responsibly while benefiting from state-of-the-art technology and expert guidance. This partnership underscores a shared vision of a cleaner, more efficient future for the region’s industrial landscape.

Purification Catalysts

We are committed to providing innovative purification catalysts that enhance efficiency and sustainability in the refining and petrochemical industries. Our advanced catalysts are designed to meet the stringent demands of modern processing, ensuring optimal performance and compliance with environmental regulations.

Together, BASF and Petrotec offer comprehensive services, including on-site technical support, performance monitoring, and training programs. This collaborative approach enables us to help our clients achieve their operational goals, improve product quality, and reduce emissions, ultimately contributing to a more sustainable future.

By choosing BASF purification catalysts, backed by Petrotec’s dedicated local support, customers in Qatar can confidently navigate the complexities of the industry while optimizing their processes for greater efficiency and environmental responsibility. Together, we are shaping the future of refining in the region, driven by innovation and commitment to excellence.

Sulfur Guard

Sulfur Guard catalysts, developed by BASF, play a critical role in the petroleum industry by enhancing the efficiency of sulfur removal processes. These advanced catalysts are designed to meet stringent environmental regulations while optimizing refinery operations. In Qatar, Petrotec has been a key partner in the deployment and integration of these innovative solutions. With a deep understanding of local market needs and operational challenges, Petrotec has successfully introduced Sulfur Guard catalysts to refineries, helping them achieve significant reductions in sulfur emissions.

Petrotec’s expertise in engineering and project management has facilitated seamless implementation of these catalysts, ensuring that refineries maximize their productivity and comply with international environmental standards. By leveraging BASF’s cutting-edge technology, Petrotec has enabled Qatari refineries to enhance their sustainability initiatives, ultimately contributing to a cleaner environment and improved public health.

Furthermore, Petrotec’s commitment to customer support and tailored solutions has strengthened the adoption of Sulfur Guard catalysts, making them a preferred choice in the region. Together, BASF and Petrotec are not just improving refinery performance; they are also paving the way for a more sustainable future in Qatar’s energy sector. This collaboration underscores the importance of innovative technologies in driving responsible industrial practices.

Chloride Guard

Chloride Guard Catalysts, developed by BASF, play a crucial role in enhancing the efficiency and longevity of catalysts used in the petroleum industry. These advanced materials are specifically designed to mitigate the adverse effects of chloride contaminants in refining processes, thereby improving catalyst performance and operational reliability.

Petrotec has been instrumental in the adoption and integration of BASF’s Chloride Guard Catalysts. By leveraging their local expertise and strong industry connections, Petrotec has facilitated the introduction of these innovative solutions to refineries across Qatar. Their efforts have not only enhanced operational efficiencies but have also contributed to the sustainability goals of the region by minimizing catalyst degradation and extending service life.

The collaboration between BASF and Petrotec exemplifies a successful partnership that combines cutting-edge technology with local market knowledge. Together, they are addressing the challenges posed by chloride contaminants, ensuring that Qatari refineries operate at peak performance while adhering to stringent environmental standards. This synergy underscores the importance of innovative catalyst solutions in driving the future of the petroleum industry in Qatar and beyond, positioning the region as a leader in refining excellence.

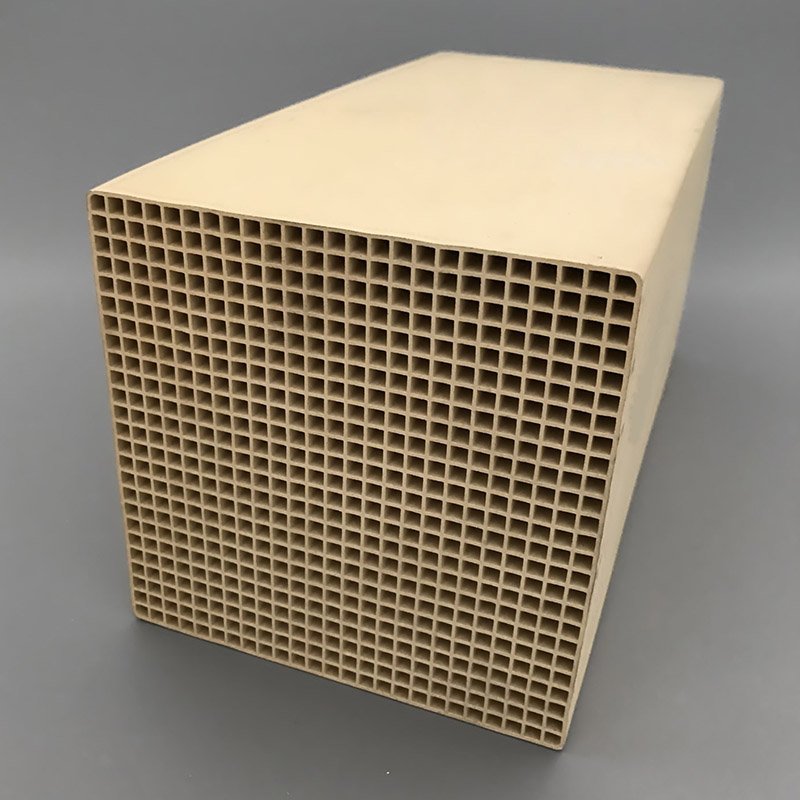

DeNOx Catalyst

BASF’s DeNOx honeycomb catalysts play a crucial role in reducing nitrogen oxide (NOx) emissions from industrial processes, particularly in the petrochemical sector. These catalysts are designed for high efficiency and durability, making them essential for meeting stringent environmental regulations. In Qatar, where the petrochemical industry is a significant part of the economy, the demand for advanced emission control technologies is ever-increasing.

Petrotec has been a key partner in promoting and implementing BASF’s DeNOx solutions in Qatar. With its deep understanding of the local market and strong relationships with industry stakeholders, Petrotec has facilitated the adoption of these cutting-edge catalysts. By providing tailored solutions that meet the specific needs of Qatari facilities, Petrotec has helped optimize the performance of BASF’s catalysts, ensuring compliance with both local and international emissions standards.

The collaboration between BASF and Petrotec not only enhances operational efficiency but also contributes to Qatar’s commitment to sustainable development. As the nation continues to expand its petrochemical capacity, the partnership stands as a testament to the effectiveness of innovative technology in addressing environmental challenges while supporting industrial growth. Together, they are paving the way for a cleaner, more sustainable future in Qatar’s petrochemical landscape.

Molecular Sieves

Molecular sieves are highly effective adsorbent materials widely used for gas and liquid separation, dehydration, and purification processes. Composed of crystalline aluminosilicates, these materials possess a unique porous structure that selectively traps molecules based on size and polarity. This makes them invaluable in various industries, including petrochemicals, natural gas, and pharmaceuticals.

At Petrotec, we recognize the critical role that molecular sieves play in enhancing operational efficiency and product quality. With our extensive experience in the market, we are proud to offer a range of high-performance molecular sieves tailored to meet the specific needs of our clients in Qatar. Our products are designed to optimize processes such as gas drying, hydrocarbon separation, and solvent recovery.

Fluid Catalytic Cracking Catalyst

Fluid Catalytic Cracking (FCC) is a crucial process in the petroleum refining industry, transforming heavy feedstocks into valuable products like gasoline and diesel. Grace’s FCC catalysts are engineered for optimal performance, offering enhanced conversion rates and selectivity, which maximize yield and minimize operational costs. With advanced formulations, Grace ensures that its catalysts meet the diverse needs of refiners, facilitating efficient processing while adhering to environmental standards.

Petrotec stands out as a key partner in Qatar, delivering local logistical support and stocking capabilities. With a deep understanding of the regional market and its unique challenges, Petrotec ensures timely and reliable delivery of Grace’s FCC catalysts to refining facilities across the country. Their dedicated team provides seamless coordination, minimizing downtime and ensuring that refineries can maintain optimal operations without interruption.

Petrotec’s commitment to excellence means that customers can rely on swift response times and efficient supply chain management, making it easier to adapt to changing production demands. Together, Grace’s innovative catalysts and Petrotec’s unparalleled logistical expertise create a powerful synergy, enabling Qatari refineries to achieve outstanding results in their FCC processes.

Fluid Catalytic Cracking Additives

Fluid Catalytic Cracking (FCC) additives play a crucial role in enhancing the efficiency and profitability of refineries. Grace’s advanced FCC additives are designed to optimize catalyst performance, improve product yields, and reduce emissions, ensuring that refiners can meet the ever-increasing demands of the market. These innovative solutions not only boost operational effectiveness but also contribute to sustainability goals by minimizing environmental impact.

Petrotec stands out with its exceptional logistical support ans stocking capabilities, ensuring that Grace’s FCC additives are delivered seamlessly to local refineries. Petrotec’s commitment to excellence in supply chain management guarantees timely delivery and efficient distribution, enabling customers to maintain continuous operations without interruption. Their local expertise allows for tailored solutions that meet specific refinery needs, ensuring that clients can maximize the benefits of Grace’s cutting-edge additives.

By combining Grace’s high-performance FCC additives with Petrotec’s flawless logistical capabilities, refineries in Qatar can achieve optimal results in their catalytic processes. This partnership not only enhances operational efficiency but also strengthens the competitive edge of local refineries in a dynamic global market, positioning them for sustained success and innovation in the energy sector.

DeSOx Catalyst

DeSOx catalysts from Grace are engineered to deliver exceptional performance in reducing sulfur emissions from industrial processes, ensuring compliance with stringent environmental regulations. These catalysts utilize advanced formulations that enhance the efficiency of desulfurization, providing a reliable solution for various applications, including oil and gas, refining, and petrochemical sectors.

Petrotec stands out as a key partner in Qatar, offering unparalleled logistical support to ensure the seamless integration of DeSOx catalysts into operational frameworks. With a deep understanding of the local market and industry requirements, Petrotec guarantees timely delivery and comprehensive technical assistance, minimizing downtime and maximizing operational efficiency. Their expertise in navigating regional logistics challenges allows for swift mobilization of resources, ensuring that customers receive the support they need, exactly when they need it.

This synergy between Grace’s cutting-edge technology and Petrotec’s flawless local logistics empowers companies in Qatar to enhance their sustainability efforts while maintaining optimal performance. By choosing DeSOx catalysts from Grace, backed by Petrotec’s unwavering commitment to service excellence, organizations can confidently move toward a greener future, reducing their environmental footprint without compromising on productivity. Together, they pave the way for a more sustainable industrial landscape in the region.

Refining Hydroprocessing Catalyst

GraceART’s hydroprocessing catalyst technology stands at the forefront of refining innovation, offering unparalleled efficiency and effectiveness in the treatment of hydrocarbon feedstocks. Designed to enhance the quality of fuels and lubricants while minimizing environmental impact, these catalysts facilitate crucial processes such as hydrocracking and hydrotreating.

Petrotec plays a vital role in ensuring the successful implementation and maintenance of GraceART’s hydroprocessing solutions across Qatar. With a deep understanding of local refining needs and challenges, Petrotec provides tailored support and services to optimize catalyst performance and operational reliability. Their dedicated team of experts offers comprehensive technical assistance, from catalyst selection to on-site training and troubleshooting.

This local support not only ensures that refineries can achieve maximum yield and efficiency but also fosters a strong partnership that drives innovation within the region’s hydrocarbon sector. By leveraging GraceART’s cutting-edge technology and Petrotec’s localized expertise, Qatar’s refining industry is well-positioned to meet both domestic and international energy demands sustainably. Together, they are committed to advancing hydroprocessing capabilities, contributing to a more efficient and environmentally responsible future in energy production.

Activated Carbon

NORIT® Activated Carbon offers specialized adsorption solutions designed for the Energy and Water industries, serving as a versatile adsorbent that effectively eliminates contaminants to enhance operational efficiency and environmental adherence. Due to its substantial surface area and pore structure, Norit’s activated carbon exhibits remarkable adsorption capacity for hydrocarbons, volatile organic compounds (VOCs), mercury and other impurities. Its properties enable precise impurity removal, catering to optimizing processes. Additionally, activated carbon’s re-generability minimizes costs and waste generation, aligning with sustainability goals. Norit provides extensive activated carbon solutions for amine purification, steam condensate polishing, mercury removal, deodorization and water treatment, and are available in various grades such as powdered, granular, pellets, etc.

Bed Support Balls

Petrotec is a leading provider of engineered solutions in Qatar, specializing in bed support systems and ceramic balls for various industrial applications. Our advanced bed support technology ensures optimal performance in filtration and separation processes, enhancing efficiency and reliability in demanding environments.

We utilize high-quality ceramic balls that are engineered for durability and chemical resistance, making them ideal for use in oil and gas, petrochemical, and wastewater treatment industries. These ceramic balls provide excellent strength and stability, effectively supporting bed structures while minimizing pressure drops and maximizing flow rates.

Petrotec’s commitment to quality is reflected in our rigorous testing and quality assurance processes, ensuring that every product meets international standards. Our team of experts collaborates closely with clients to develop customized solutions tailored to specific operational needs, providing technical support and guidance throughout the project lifecycle.

With a strong local presence and deep industry knowledge, Petrotec is poised to meet the growing demands of Qatar’s rapidly evolving market. Our capabilities in bed support systems and ceramic ball production position us as a trusted partner for businesses seeking reliability and innovation in their operations.

Desiccants

In the arid climate of Qatar, where humidity can significantly impact the integrity of materials, desiccants play a crucial role in moisture control. Petrotec offers advanced desiccant solutions tailored to meet the unique challenges faced by various industries in the region.

Desiccants, substances that absorb moisture from the air, are essential for preserving the quality of products and preventing deterioration. Petrotec’s offerings include silica gel, molecular sieves, and activated alumina, each designed for specific applications such as protecting electronic components, pharmaceuticals, and food products.

The effectiveness of these desiccants is rooted in their ability to maintain optimal humidity levels, which is vital for extending shelf life and ensuring product reliability. Petrotec’s state-of-the-art manufacturing processes guarantee high purity and performance standards, crucial for sectors where precision is paramount.

Furthermore, Petrotec’s local expertise allows for customized solutions that address the environmental conditions of Qatar. By understanding the interplay between temperature, humidity, and material sensitivity, Petrotec ensures that clients receive tailored desiccant systems that enhance product stability and operational efficiency. This commitment to quality and service positions Petrotec as a trusted partner in Qatar’s moisture control landscape.