Chemical Cleaning

Chemical Cleaning

We offer a wide range of chemical cleaning and maintenance services to our clients in the Oil and Gas, Chemical and Petrochemical and Power industries. We have a successful track record in dealing with the following equipment:

- Plate exchangers

- Train exchangers of crude oil

- Evaporators and condensers

- Filters

- Process lines

- Gas supply lines

- Air supply lines

- Distillation columns

- Cooling towers

- Air coolers

- Fire protection water systems

- Cooling oil and lubrication circuits

- Diesel oil circuits

- References

- Case Studies

Chemical Cleaning Applications:

Preoperational Descaling

Main objectives of preoperational descaling:

- To remove the stored scales (oxides, dust and other debris) during the construction of various types of plant.

- To form a protective film over the de-scaled surface which is resistant to corrosion.

- Reduction of commissioning time.

One Phase Clean:

Continuous research and development of new technologies has allowed SOLARCA to apply the “one phase clean” treatment in pre-commissioning de-scaling. This cleaning concept has great advantages over the traditional methods:

- Reduction of the time required for chemical cleaning.

- Lower water consumption.

Combined Cycle Chemical Cleaning

Based on wide experience in this type of work, SOLARCA offer the benefit of complete pre-commissioning services which include:

- Hydrostatic pressure testing

- Pre-commissioning de-scaling of boilers and pre boilers

- Gas line de-scaling, blowing and drying

- Chemical cleaning of service water systems

- NOX control water injection system cleaning

- Chemical cleaning systems to suit client's requirements

- Auxiliary steam supply

- Steam and air blowing cleaning services

- Magnetite formation

Power Station Cleaning

We also offer Chemical cleaning services to conventional Thermal Power Stations which include:

- Chemical cleaning of water and steam systems.

- Furnace side chemical cleaning of boilers.

- Cooling system components chemical cleaning.

- Condenser chemical cleaning.

- Chemical cleaning and flushing of oil systems.

- Calorifier chemical cleaning.

Tank chemical cleaning

SOLARCA has the equipment required to carry out chemical cleaning of tanks and deposits in columns with rotating ball sprays, without requiring entry of personnel into the confined space. Our computerized equipment allows working with different chemical agents, such as organic or inorganic acids, alkalis and surfactants in order to leave surfaces de-scaled and passivated. The advantages that this technique offers are:

- Maximum safety during the process.

- Elimination of risk due to entry of confined spaces.

- Decrease in the volume of chemical solution required.

- Quicker and more efficient execution of the work.

- Breathable atmosphere measurers, autonomous equipment, and rescue teams are not required.

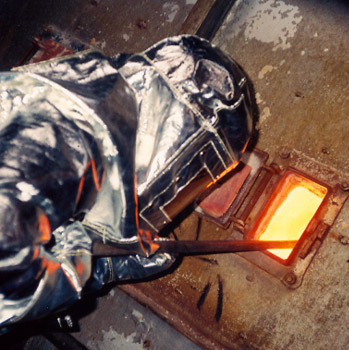

Online Furnace Cleanings

A process furnace, as well as any other equipment where heat is interchanged, requires surfaces which are as clean as possible in order to obtain the maximum yield. The use of increasingly heavier fuels creates a greater build-up of deposits both in radiation and convection areas. This creates a significant loss of yield and production capacity. For several years, SOLARCA has been successfully applying this new “on-line” cleaning technology to the radiation and convection areas of process furnaces, arranged by a specialized staff with great experience. This method of cleaning offers the following advantages:

- An innovate, effective, quick and safe technique.

- Applicable to any sort of furnace.

- Allows recovery of the unit's yield without shutting down the unit.

- Quick recovery of the cleaning costs