Seal Service Centre

Seal Service Centre

Mechanical Seals are critical to maintaining safe and reliable running of vital process equipment. From complex refining techniques to everyday water handling, Mechanical Seals are considered state-of-the-art equipment, and designed to seal off any type of rotating equipment. Mechanical Seals safely contain product that can be expensive, hazardous or flammable.

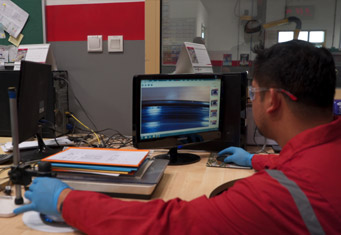

Petrotec, in association with Flowserve, has initially established the mechanical seal repair facility back in 2006. Strategically located in street 39, Salwa Industrial Area, the facility incorporate a fast track workshop and fully trained and Flowserve certified engineers and technicians, offering refurbishment, repair and static pressure testing of mechanical wet seals plus a variety of asset management and reliability optimization services.

In 2019, in partnership with Flowserve, Petrotec has expanded this facility by incorporating a dry gas seal repair and testing workshop. Petrotec can now offer the refurbishment and dynamic testing of compressor seals. Our achievements include successful seal repair agreements with many key oil and gas companies in Qatar for several years.

- References

- Case Studies

Vineeth Venugopal Head of Sales– Rotating Equipment

- +974 44238601

- +974 33477073

Partners

Service Capablities

- Inspection, refurbishment, repair and testing of all Flowserve mechanical wet seal and dry gas seal variants, as well as other brands (Vendor-X repair program).

- Inventory for Flowserve spare parts to meet emergency seal repairs. Spare parts are held on behalf of individual customers as bonded stocks in order to reduce supply times.

- Vendor stocking program for dry gas seals – inventory management of customer seals (stocking and seal requalification and extended warranty).

- Condition reporting and seal failure analysis to provide evidence of potential process or equipment problems to improve seal life.

- Static pressure testing for mechanical wet seals, not limited to but including API 682 test requirements.

- Dynamic test-run of compressor dry gas seals.

- Field service support (troubleshooting, installation and commissioning support).

- Engineering support services including failure analysis.

- System upgrade consultation.

- Training to clients including engineers, technicians and operators.

Workshop Capabilities:

- Downdraught machine.

- Heavy duty cleaning machine.

- Ultrasonic cleaner.

- Fine bead blasting machine.

- Lathe machine for machining hardware components.

- Diamond flat lapping/polishing machine.

- Monochromatic light band machine.

- API test bench.

- Dry gas seal dynamic tester rig:

- Max. speed: ~25k rpm

- Max. test pressure: ~300 bar (compressor up to 350bar)

- Max. shaft diameter: ~300mm

- Max. internal Flowserve seal size: KZ 81 (capable for all sizes)

- Spring load tester.