Lokring Technology

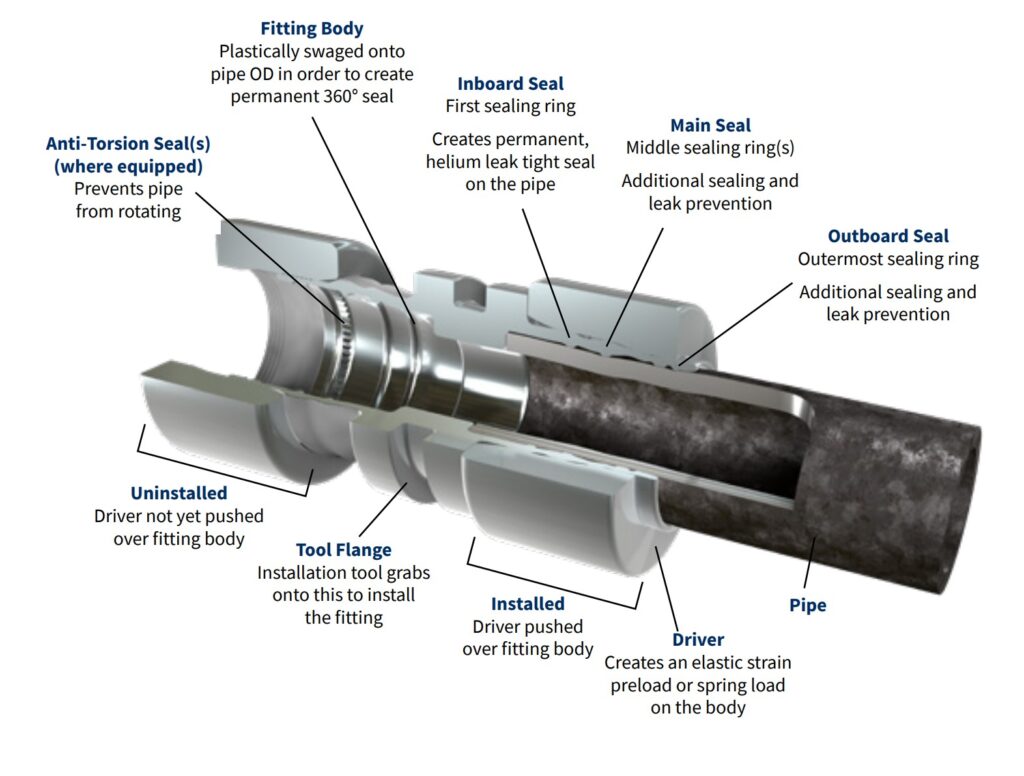

Lokring Technology offers an innovative, weld-free solution for high-integrity pipe connections. Using patented Elastic Strain Preload (ESP®) technology, Lokring connectors create permanent, leak-tight, metal-to-metal seals without the risks associated with welding, threading, or flanging. This makes Lokring ideal for general maintenance, shutdowns, offshore installations, including but not limited to hazardous or confined spaces where hot work should be avoided and/or where rapid connection of small-bore piping is required.

Petrotec is the authorized Lokring technology provider in Qatar.

Petrotec is the authorized Lokring technology provider in Qatar.

Key Advantages:

-

Weld-Equivalent Sealing Integrity

-

Fast, Field-Friendly Setup

-

Qualified to ANSI/ASME B31.x codes for High-Performance Use

-

Certified Lokring tool kits and trained installer support

-

Rapid deployment for shutdowns and emergency repair work

Key Capabilities

Core Scope of Services

- Supply of Lokring fittings in CS, SS, Cu-Ni, LTCS, and Super Duplex (SDSS) materials

- On-site pipe repair and emergency sealing solutions using Lokring technology

- Tool rental and mobilisation for shutdown applications

- Installer training, qualification, and technical supervision

- Retrofit spool fabrication and field modification services

Technology Features

- Patented Elastic Strain Preload (ESP®) metal-to-metal sealing

- Hot-work free installation – Installations are done without welding, eliminating fire permits and hazards in explosion-prone environments.

- Qualified for quick, no-thread, no-purge installation using hydraulic tools—ideal for tight-access and shutdown environments.

- Leak-tight performance equivalent to welding (Helium leak certified)

- Compatible with ANSI/ASME B31.x piping codes, for high-pressure, sour service, offshore, and industrial piping systems.

- No O-rings or elastomeric elements – all-metal permanent joints

Product Range

- Available in Materials & Sizes:

- Carbon Steel (MAS‑3000): 1/4” – 4” NPS (Schedule 40/80; ½–1″Schedule 160)

- 4130 Alloy Low‑Temperature Carbon Steel (LTCS‑333): 1/2” – 4” NPS (Schedule 40/80)

- 316L Stainless Steel (SS40/SS‑3300): 1/4” – 3” NPS (Schedule 10/40/80)

- Copper‑Nickel (CN‑200/CN‑700): 1/4” – 2” NPS

- Other alloys (e.g., Super Duplex) – Consult Petrotec for availability

Available in typical shapes

- Coupling (Straight,

- Reducing, repair)

- Tees (straight & branch)

- Reducers

- Flanges

- Elbows (45°, 90° short & long radius)

- Caps

- Adapters

Equipment & Tooling

- Hydraulic installation tools for tight-access applications

- Portable tooling kits for offshore and plant use

- Full installation support with simple inspection protocols

Industries & Applications

- Oil & Gas (onshore, offshore, upstream/downstream)

- Power and utilities infrastructure

- Marine and shipbuilding sectors

- Chemical and petrochemical processing

- Emergency repair and shutdown maintenance