Condition Monitoring- Electrical Assets

Petrotec offers predictive maintenance and condition monitoring solutions that enhance equipment reliability, extend asset lifespan, and reduce costly downtime. Our suite of diagnostic services; including Thermography, Dissolved Gas Analysis (DGA), Partial Discharge Monitoring, and Harmonic & Power Quality Analysis – empowers you to detect faults before they turn critical.

Thermography Services

Thermography is a non-invasive diagnostic technique that uses infrared (IR) imaging to detect abnormal heat patterns in electrical and mechanical equipment. By identifying temperature anomalies in real-time, thermography helps predict potential failures without requiring system shutdown or physical contact. It is a vital part of any condition-based or predictive maintenance strategy.

- Detects thermal anomalies in electrical systems

- Identifies overheating in components, connections, and equipment

- Enhances preventive maintenance by identifying issues before failure

- Reduces unplanned outages and improves system reliability

- Supports safety compliance and risk mitigation

- Conducted by certified technicians using advanced thermal imaging tools

- Wide temperature detection range: –10°C to 1200°C

- Utilizes ThermoView software for industrial applications

Key Services

-

LAN/Ethernet with PoE for seamless communication and web server integration

-

Histogram & isotherm analysis

-

Area and point trend data collection

-

Offline image viewing and comparison

-

Optimized for industrial monitoring with reliable, real-time diagnostics

1.Dissolved Gas Analysis (DGA)

Dissolved Gas Analysis (DGA) is one of the most reliable and widely used techniques for assessing the internal condition of oil-filled transformers. It involves detecting and measuring gases dissolved in the insulating oil that are generated due to thermal, electrical, or chemical faults. Our DGA services provide early warning of developing faults, enabling proactive maintenance and avoiding catastrophic transformer failures. Petrotec has partnered with GE to deliver industry-leading DGA services in Qatar.

Petrotec is an authorized partner of GE in Qatar.

Key Services:

- Critical diagnostic tool for assessing transformer health

- Detects early signs of internal arcing, overheating, and insulation degradation

- Enables condition-based maintenance and helps prevent unexpected failures

- Supports life extension and reliability of power assets

- Performed using advanced GE diagnostic equipment and standards

2.Partial Discharge Monitoring

Partial discharge (PD) is a subtle electrical phenomenon that signifies the early stages of insulation degradation in high-voltage assets. Though not immediately destructive, undetected PD activity can escalate into severe faults, leading to costly failures and unplanned outages. Our PD testing and monitoring solutions provide precise, non-invasive diagnostics to detect, evaluate, and locate insulation defects — allowing for timely corrective action and improved system reliability.

Partial discharge measurement allows evaluation of the dielectric condition in high-voltage equipment, enabling detection and localization of electrical treeing within insulation. Petrotec delivers advanced PD diagnostics for predictive maintenance and grid reliability in partnership with Omicron.

Key Services:

- Identifies early-stage faults in MV/HV equipment

- Prevents catastrophic failures through timely intervention

- Applicable to switchgear, transformers, cables, and GIS

- Enables condition-based maintenance and asset management

- Offers non-invasive testing – both online and offline

- Improves system reliability and extends equipment lifespan

Petrotec is an authorized partner of Omicron in Qatar.

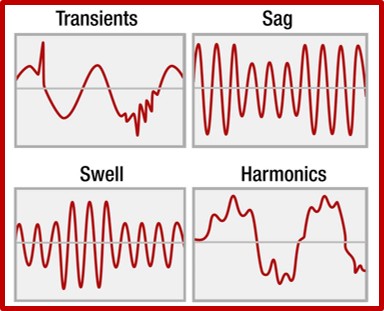

3.Harmonic and Power Quality Analysis

Power quality plays a vital role in the performance, lifespan, and safety of electrical systems. Poor power quality, particularly due to harmonic distortion, voltage fluctuations, and unbalanced loads, can lead to equipment malfunctions, increased energy losses, overheating of components, and even production downtime. Our Harmonic and Power Quality Analysis Services are designed to identify and diagnose such disturbances, helping you implement corrective actions that ensure system reliability and regulatory compliance.

Harmonics are voltages or currents at multiples of the fundamental frequency, typically caused by non-linear loads such as rectifiers, discharge lighting, or saturated magnetic devices.

Key Benefits:

- Increases RMS and peak current, leading to overheating and efficiency losses

- Affects performance and lifespan of electrical machines, transformers, and sensitive equipment

- Contributes to nuisance tripping, operational instability, and higher energy costs

- Critical for maintaining a stable, efficient, and reliable electrical system

- Enhances energy performance and supports compliance with international standards

Key Services:

- Detection of harmonics, transients, voltage sags/swells, and flicker

- Simulation of harmonic current and voltage sources

- Reduction of nuisance trips and performance disruptions

- Design, supply, and testing of harmonic filters

- Reporting of harmonic voltage/current distortion limit violations

- Evaluation of compliance with IEEE 519 and other standards

- Electrical energy audits and power optimization solutions.