Pump Services 2025

Pumps Services

Petrotec Pump Services Center specializes in delivering end-to-end aftermarket solutions designed to ensure optimal performance, reliability, and longevity of pumping equipment. With proven expertise across Oil & Gas, Power & Desalination, Industrial, and Cryogenic applications, we deliver tailored support to meet the diverse needs of our clients.

Petrotec Pump Services Center, the authorized repair workshop for Flowserve pumps and Pleuger submersible pumps, offers direct access to OEM engineering expertise for advanced troubleshooting and upgrades alongside with OEM-trained specialists.

Key Benefits

-

Minimized Downtime

Proactive maintenance and rapid response to issues reduce unexpected downtime.

-

Customized Solutions

Tailored solutions to meet specific operational needs.

-

Long-Term Reliability

Comprehensive service and maintenance ensure lasting production and reliability of your equipment.

-

High Standards

Assurance of high-quality service and adherence to API and industry standards.

-

Reliable Service

Consistent and dependable service ensures customer satisfaction.

-

Local Presence

Petrotec offers local support and technical expertise and guarantees the highest standards of maintenance and repair

-

Quick Response

Being based in Qatar allows for faster response times and better understanding of local market needs.

-

Personalized Support

Personalized and attentive customer support.

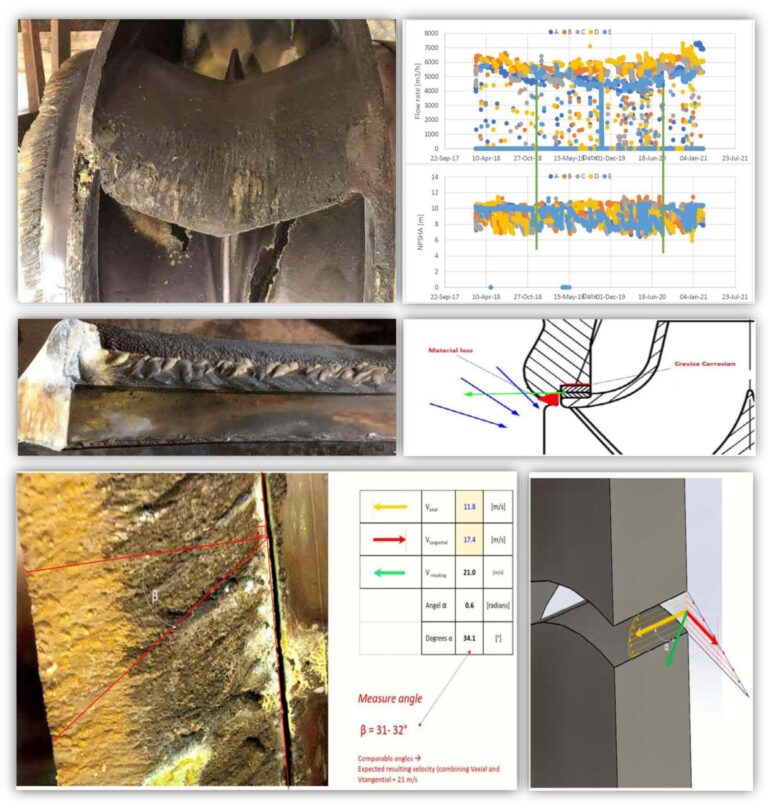

Service Capabilities

Complete Overhauling

Full refurbishment of centrifugal, submersible, and cryogenic pumps, including blasting, ultrasonic cleaning, welding, precision machining, dynamic balancing, and painting.

Performance Testing

Thorough pump performance evaluations conducted in workshop for Overhung pumps (OH) with testing parameters up to 1500m3/h or 200 kW and maximum piping size of 10 inch.

OEM Engineering Support

Direct access to OEM engineering expertise for complex diagnostics, custom solutions, upgrades, and retrofits.

Upgrades and Retrofits

Pumps and parts upgrades including parts protection and specialized coatings, non-metallic wear parts, bearing-housing upgrades, and more.

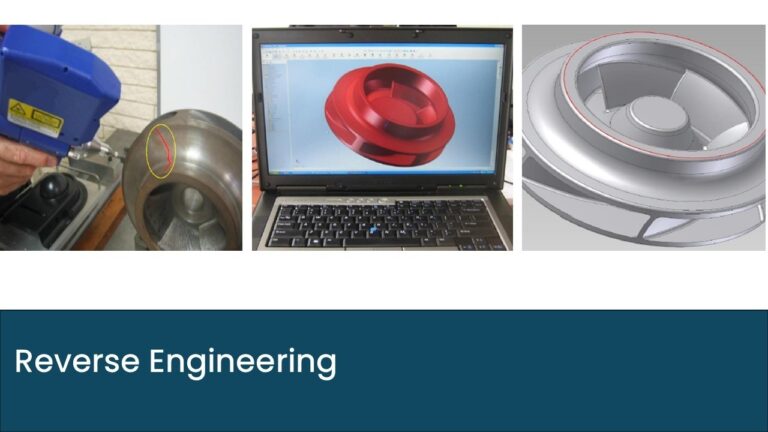

Reverse Engineering

Comprehensive reverse engineering solutions for pump components, encompassing advanced 3D scanning, material characterization, detailed drawing generation, and manufacturing processes to reproduce obsolete or unsupported parts.

Training

Offering both theoretical instruction and practical, hands-on training sessions for customers.

Onsite Activities

Ensuring optimal operation through on-site pre-commissioning, and commissioning of pumps:

- Installation

- Alignment (standard and laser)

- Start up

- Advanced Troubleshooting: Utilizing vibration monitoring and thermal imaging techniques.

- Performance testing of pumps: Evaluating the pump’s operation directly within its installed environment via monitoring and data collection (pressure, flow rate, temperature, vibration, power consumption, and speed)

- Performance analysis

Submersible Pump Repairs

Complete overhauls of submersible pumps including testing, rewinding, curing, and no-load testing of the electrical motors.