Valves Aftermarket Services

Valves Aftermarket Services

Our Valves service center specializes in delivering comprehensive aftermarket services for valves, actuators, and control systems supporting end users across Qatar to ensure peak performance, reliability, and extended equipment lifespan.

Our Valves service center is the approved workshop for the following:

- Masoneilan Control Valves (MARC)

- Consolidated™ Pressure Relief Valves (Green Tag)

- Rotork actuators

We have successfully executed key projects across various sectors, including valves testing, calibration and certification for greenfield and brownfield projects, in addition to valves overhauling during shutdowns and turnarounds.

Key Benefits

-

Technical Expertise & Specialized Support

Our skilled technicians provide in-depth knowledge, ensuring precise diagnostics, troubleshooting, and tailored solutions for valve performance optimization

-

Reduced Downtime & Increased Operational Efficiency

Quick repairs and maintenance minimize operational interruptions, keeping your systems running smoothly with minimal disruptions

-

Compliance & Certification Assurance

Our service center adheres to industry standards and regulatory requirements, ensuring your valves meet safety and performance specifications

-

Customization & Engineering Support

We offer tailored solutions to meet specific operational requirements, including modifications, upgrades, and enhancements for better efficiency

-

Stock Availability & Spare Parts Management

A well-maintained inventory ensures quick access to spare parts, eliminating long lead times and ensuring continuous operation

-

Improved Asset Longevity

Proper servicing extends the life of valves, reducing replacement costs and maximizing asset utilization

-

In-country Value (ICV)

Supporting local expertise and reducing dependence on foreign resources

-

Improved Delivery Time

Our proximity to clients significantly reduces lead times, ensuring quicker turnaround for maintenance, repairs, and part replacements

-

Supply Chain Optimization

A well-integrated local service center streamlines logistics, minimizes delays, and ensures consistent availability of essential components, reducing operational risks

-

Access to Client Inspection

Clients have the convenience of inspecting their equipment firsthand, ensuring quality control and confidence in the service provided

Service Capabilities

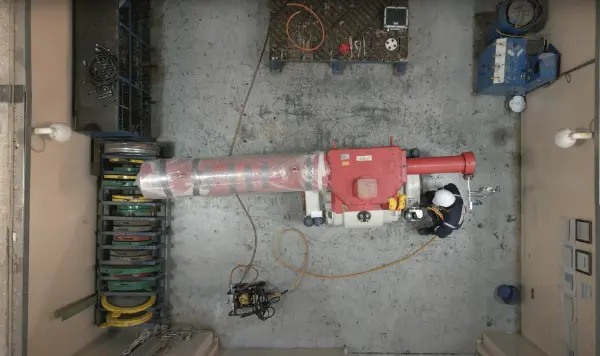

Complete Overhauling of Valves and Actuators

Pressure and Functional Testing of Valves

Pressure and functional testing of valves in full compliance with API standards:

- Shell, backseat and Seats Integrity – Pressure testing to confirm tightness and resilience

- Actuator Functionality – Evaluating torque, open-close timing, leak resistance, and overall operational efficiency

Overhauling, Testing and Calibration of PSVs

Expert overhauling, calibration and testing for all PSV types, including conventional, pilot, and bellow designs:

- Gas Pressure Testing – Up to 200 BarG

- Liquid Pressure Testing – Up to 800 BarG

- Valve Size Capability – Handling valves up to 14” in diameter

Valve Automation Services

- Retrofit automation of manual valves with electric, pneumatic, or hydraulic actuators.

- Design, engineering, and fabrication of hydraulic and pneumatic control panels

- Diagnostics and performance optimization of existing control systems

- Valves modification services including engineering and execution of modifications for control valves, ESDVs, BDVs, HIPPS systems, etc., to meet new process or customer requirements.

Obsolescence Management

Identification of obsolescence for Masoneilan valves and Rotork actuators, offering upgraded solutions for valve bodies, actuators, postioners, and controllers to ensure continued performance without disruption.

Electronic Valve Testing (EVT)

EVT is a non-invasive method used to assess the performance and safety of pressure safety and relief valves while they remain in service. The process involves applying a controlled force to the valve spindle, simulating the opening pressure to determine the valve’s set pressure, and then comparing the applied force with the actual system pressure for validation.

Key Benefits of EVT:

- In-situ testing: Eliminates the need for system shutdown, minimizing downtime.

- Fast and portable: Suited for field applications with minimal disruption to operations.

- Accurate diagnostics: Verifies valve performance, confirms set pressure, and detects leaks or mechanical faults.

Onsite services for both Onshore & Offshore

Leveraging ATEX-certified mobile workshops, designed for Zone II hazardous areas, to deliver on-site valve servicing, repair, and testing, significantly reducing turnaround time during planned outages.

Personalized Service

- Valves fail condition modification

- Valves limit stoppers design and installation

- Turbine purging and testing

- Oxygen cleaning of equipment